Electronic Circuit Board Design and Assembly Services

Home / Services

First Choice Assembly Services We Offer

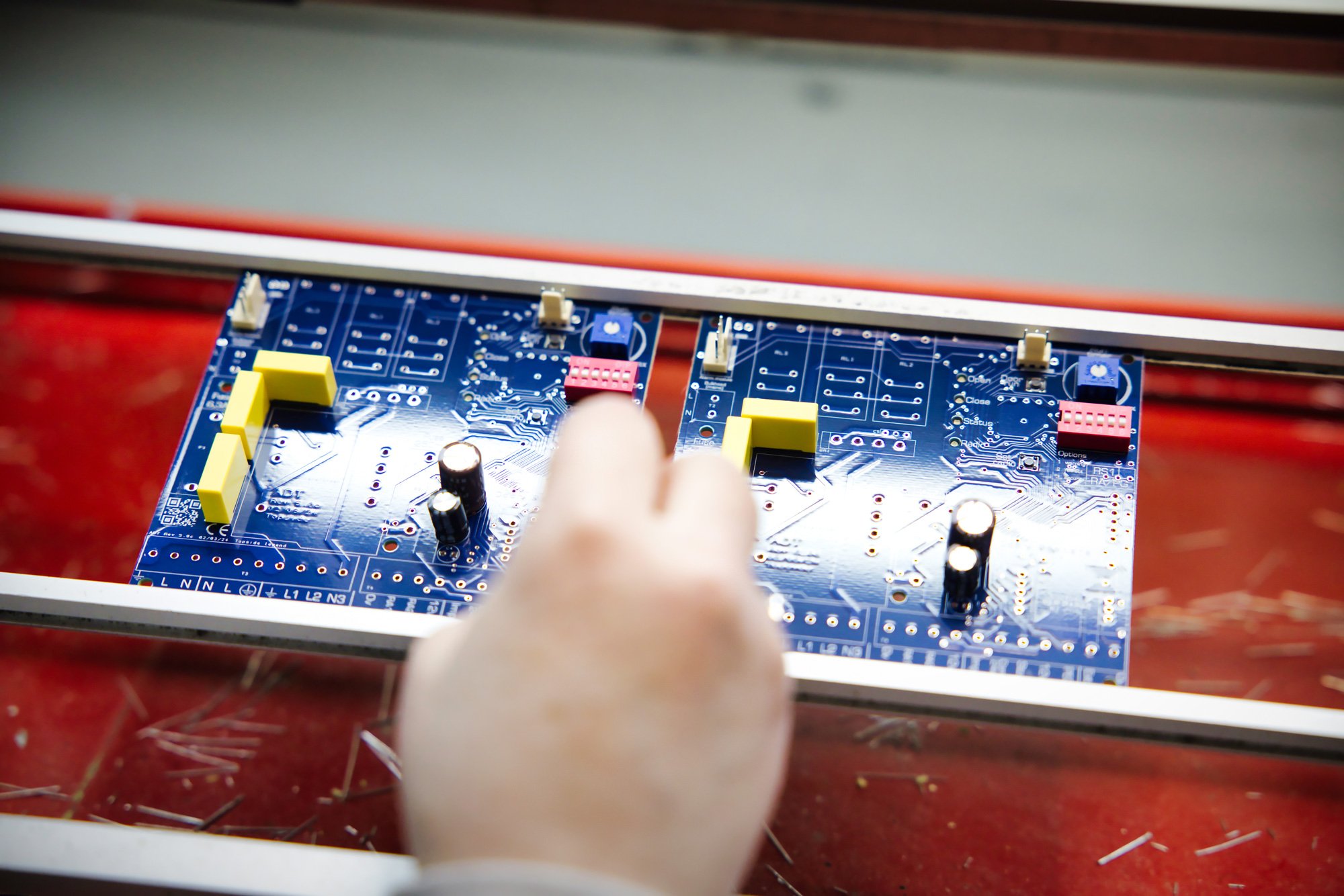

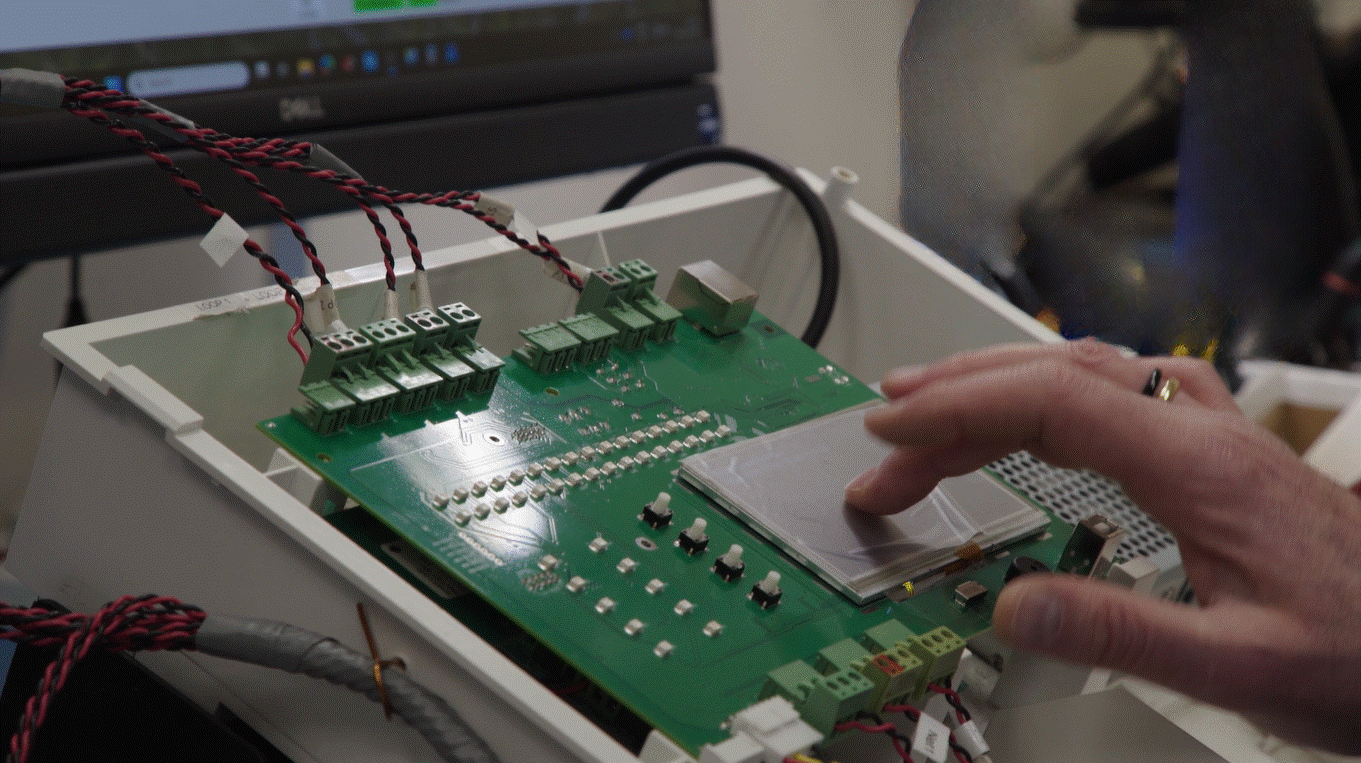

PCB assembly and production services from First Choice Assembly.

At First Choice Assembly we specialise in surface mount PCB assembly and manufacture of conventional or hybrid printed circuit boards to our client’s specification. This can be done using our own procurement of PCB components or from free issue materials, either way we will offer the same attention to detail we offer to all our clients.

FCA can be seen as an extension to your own manufacturing facility or as a company that you use on a need basis. Either way, we assure you of a responsive approach from the quotation stage straight the way through to build and despatch of your printed circuit boards.

All our PCB assemblies are 100% inspected using visual inspection or AOI (automatic optical inspection). We will also work with our clients to produce, when specified functional, test equipment to check electronic functionality and electrical integrity. We will also use client supplied test equipment.

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

Contact

What we do:

PCB Layout and Design

Purchasing (Components and Printed Circuit Boards)

Inventory Management

Surface Mount PCB Assembly

Through Hole PCB Assembly

Prototypes PCB Assembly

PCB Final Box Build

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors.

About

Have questions about our PCB assembly and manufacturing services?

We've gathered the most common questions here to help you understand our capabilities, processes, and standards. From lead times to technical specifics, our FAQs cover everything you need to know to get started with First Choice Assembly.

If you don’t see your question answered here, feel free to reach out, and our team will be happy to assist.

-

In order for us to quote on the supply of a bare printed circuit board we would need the volume you require and the Gerber file for the PCB. At this stage you would need to inform us of any specific requirements on the panelisation of the PCB or material thickness/ type or colour. If the exact requirement is not given we assume we use FR4 with 1oz copper with green resist.

-

Prototype batches can be supplied within 10 days at no extra cost. In volume using off shore supply this typically takes around 3-4 weeks with a new PCB and around 2-3 weeks on a repeat order of PCBs.

-

Tooling is an initial one off charge to cover two things. When a bare PCB is first put into production film work has to be made in order to produce the PCB. The cost of this is circa £70.00 to £200.00 depending on PCB type. If the PCB is a complex double sided PCB with fine tracks or a multilayer printed circuit board then we suggest bare board testing (BBT) to test for circuit continuity. This charge does vary depending on circuit/test complexity.

A charge will also be made for a frameless solder stencil circa £150.00 if the PCB is surface mount. This is to enable solder paste to be screen printed onto the PCB to allow for assembly of the component onto it. The solder stencil is produced from the Gerber data used to make the bare PCB. Solder stencil can be made with 72 hours. Note double sided PCB's require 2 Stencils.

These charges are only an indication and can vary depending on order value and can be free in some instances.