Introduction

Printed circuit board (PCB) assembly is the backbone of modern electronics. From everyday household gadgets to advanced industrial equipment, every electronic device relies on carefully designed and assembled PCBs to function reliably. Choosing the right PCB assembly partner ensures high-quality products, minimal defects, and faster time to market.

At First Choice Assembly, we specialise in precision PCB assembly for small to medium production runs, offering services across surface mount technology (SMT), through-hole assembly, prototyping, testing, and supply chain management. This guide will take you through the entire PCB assembly process, divided into ten key areas, each linking to a dedicated page answering the most common questions our customers ask.

Scroll down to navigate to the section where we answer all you PCB Assembly questions. If you do not see the answer to your PCB Assembly question call us on 01384 891991

Interested in our finished assembly services?

Get in touch with our team and we can supply a detailed quote for your project requirements.

Contact

1. Introduction to PCB Assembly

Understanding PCB assembly is essential for any electronics project. This section introduces the basics of PCB assembly, the different types of PCBs, and why quality assembly matters. Whether you are creating prototypes or full production runs, knowing the process helps you make informed decisions and ensures your product meets the highest standards.

4. PCB Prototyping

Prototyping allows engineers to test designs before committing to full production. This section covers rapid prototyping services, how prototypes are tested, and why early-stage evaluation saves time and costs in the long run.

7. Component Sourcing & Supply Chain

Reliable PCB assembly starts with sourcing the right components. Here we explain how we manage supply chains, procure hard-to-find parts, maintain quality while keeping production on schedule and help you save money on component sourcing.

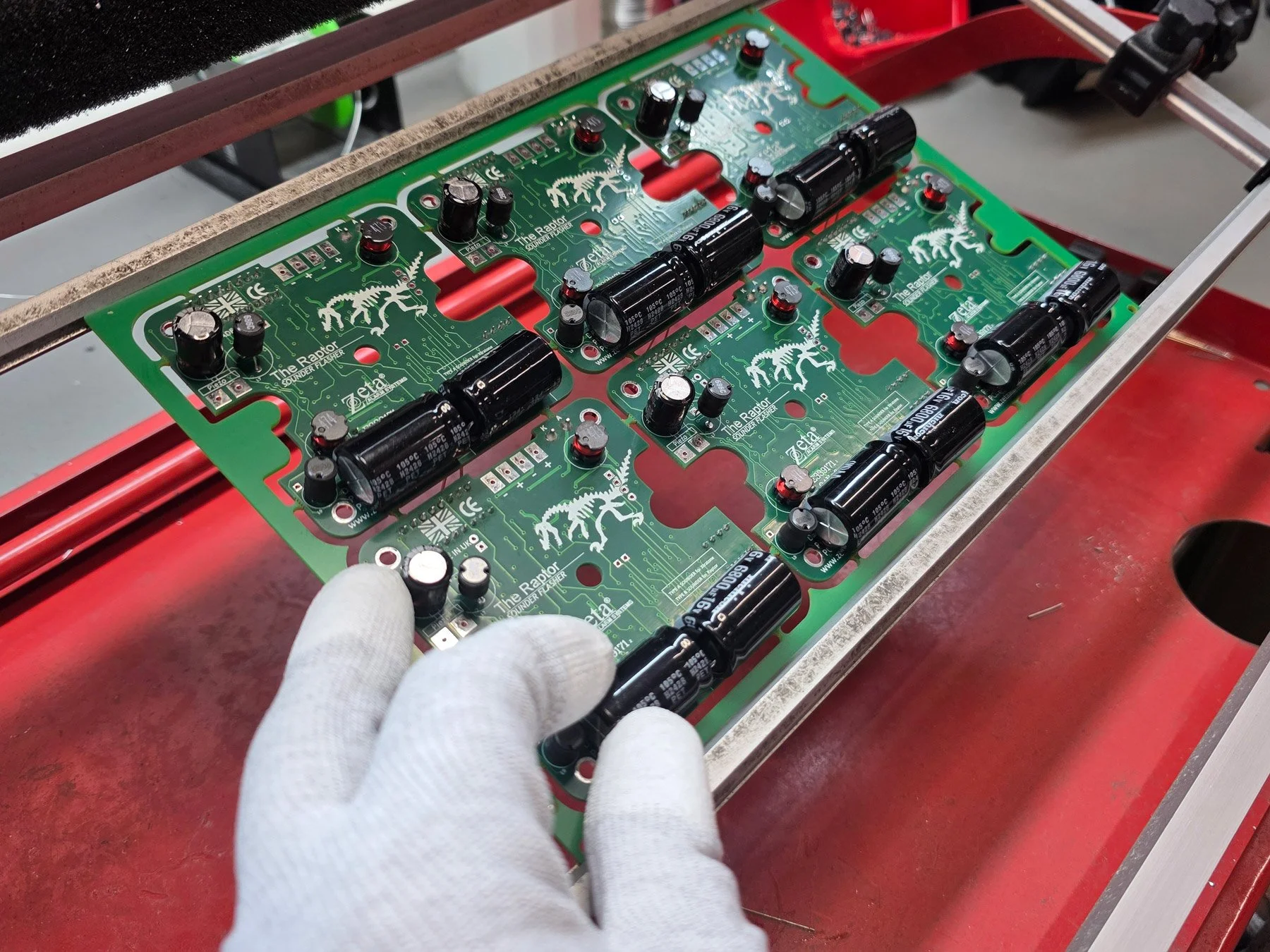

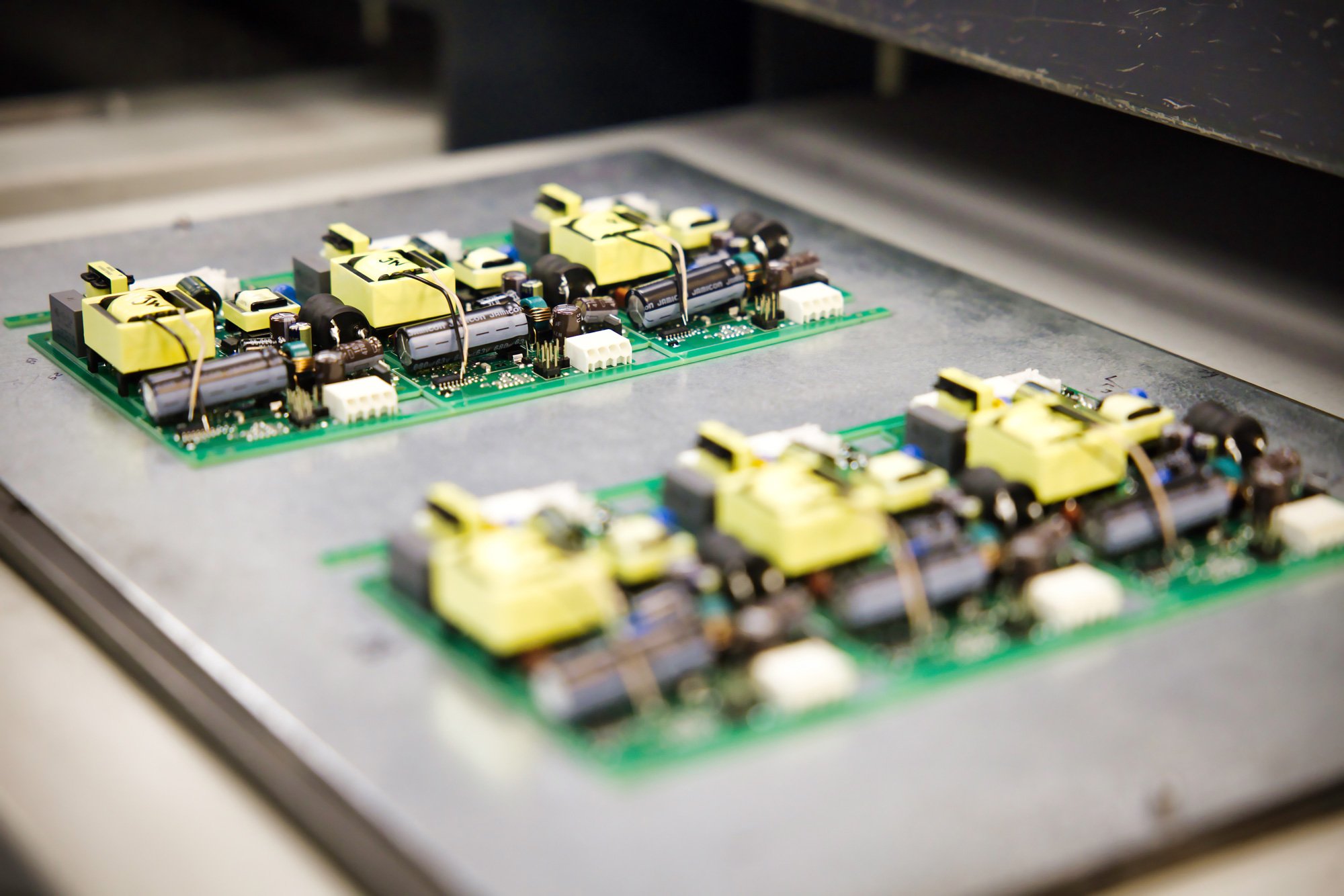

2. Surface Mount Technology (SMT) Assembly

Surface mount technology has transformed PCB assembly by allowing smaller, more complex, and highly reliable boards. This section explores the advantages of SMT, common components, and automated assembly techniques that improve speed and precision, while reducing errors.

5. PCB Testing & Quality Control

High-quality assembly relies on thorough testing and inspection. From automated optical inspection (AOI) to functional testing, this section explains the steps taken to ensure every board leaving our facility meets UK and international quality standards.

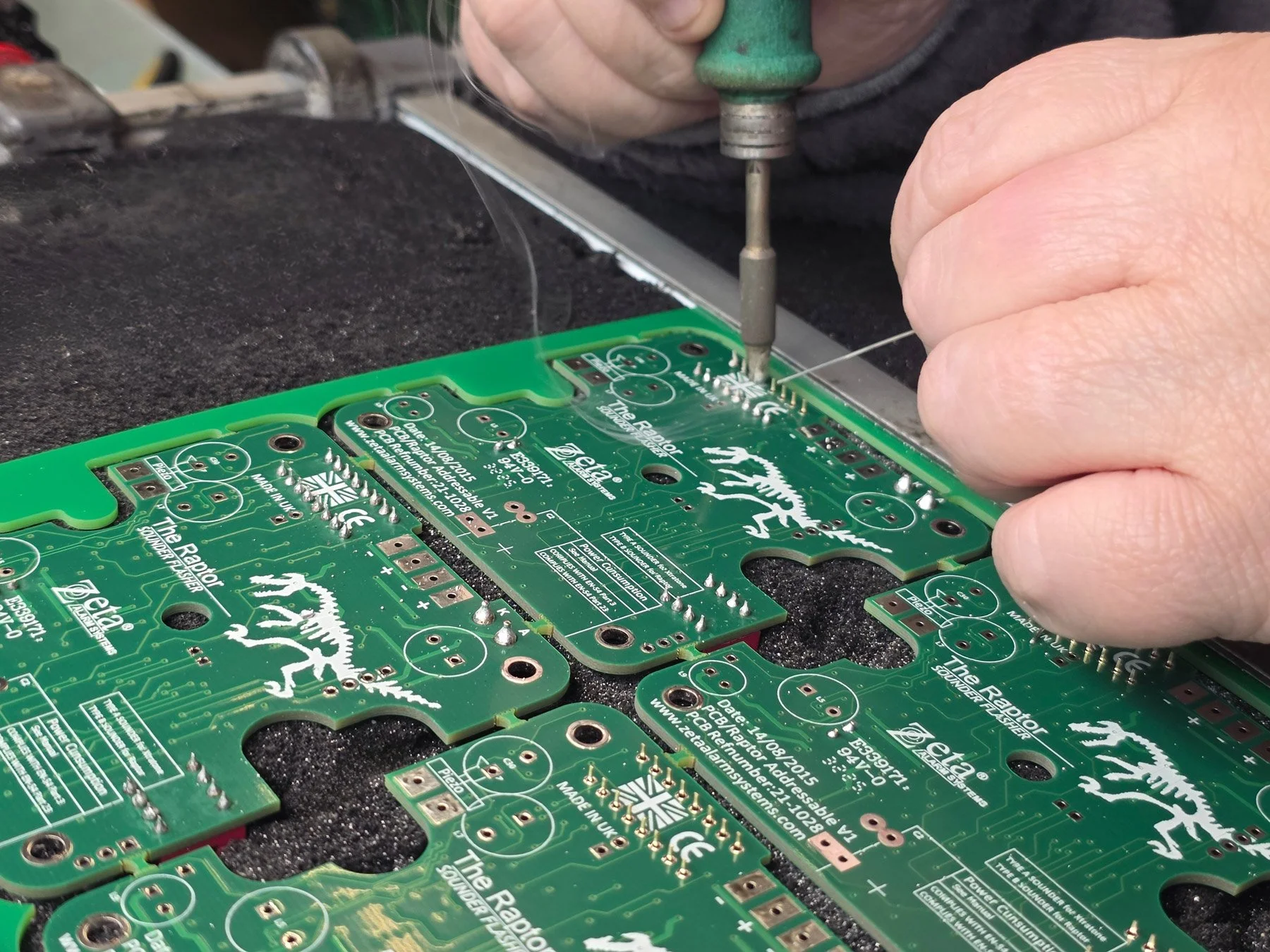

8. Rework & Repair Services

Even the best designs occasionally require adjustments. This section covers how faulty or damaged boards are identified, repaired, and tested to ensure reliability, maintaining the integrity of your electronics project.

10. Choosing the Right PCB Assembly Partner

Selecting a trustworthy PCB assembler can make or break your project. This section provides tips on what to look for, including expertise, certifications, customer service, and how First Choice Assembly supports every step from prototype to production.

3. Through-Hole PCB Assembly

Through-hole assembly remains vital for high-reliability applications and components that require extra mechanical strength. Here we discuss when through-hole is preferable, its benefits, and how modern assembly techniques combine precision with durability.

6. Small to Medium Volume PCB Production

Not every project requires mass production. This section highlights services tailored to small and medium production runs, offering flexible volumes, fast lead times, and consistent quality for UK businesses.

9. Regulatory Compliance & Standards

Meeting UK and international standards is critical for product safety and market access. This section outlines the key regulations, including RoHS, IPC standards, and quality management practices that govern PCB assembly.

Conclusion

Whether you are launching a prototype or scaling up production, understanding the PCB assembly process is key to success. The guide provides a comprehensive overview, while each section links to a detailed FAQs to answer the specific questions engineers, designers, and businesses most often ask. At First Choice Assembly we combine technical expertise, UK-based production and a commitment to quality to deliver reliable precision PCBs for every project..