Precision, reliability, and innovation define our surface mount technology assembly services. Using advanced automation and expert engineering, we create compact, high-performance circuit boards designed for modern electronic products. From LED lighting to industrial control systems, our surface mount assembly processes deliver efficiency and consistency at every stage of production.

What Is Surface Mount Technology?

Surface mount technology is the process of mounting electrical components directly onto the surface of a PCB, rather than inserting them through holes as in traditional methods. This approach revolutionised PCB manufacturing by allowing smaller, lighter, and more complex circuits to be produced at scale.

In contrast, through-hole and surface mount technology differ in how components are secured. Through-hole components are larger and inserted into drilled holes, while SMT parts such as resistors, capacitors, ICs, and LEDs sit directly on the board. This makes SMT ideal for high-density, automated production.

Common surface mount technology components include microchips, capacitors, and LEDs like the 0603 SMD LED, known for its compact size and reliability. Together, these components enable manufacturers to achieve high-speed performance, exceptional accuracy, and strong mechanical connections.

Our Surface Mount Assembly Process

At First Choice Assembly, our surface mount technology process combines precision engineering with advanced automation to guarantee consistent results across every order.

1. Solder Paste Application

The process begins with applying solder paste through a stencil onto the PCB pads. This forms the base for bonding components securely during reflow.

2. Component Mounting on PCB

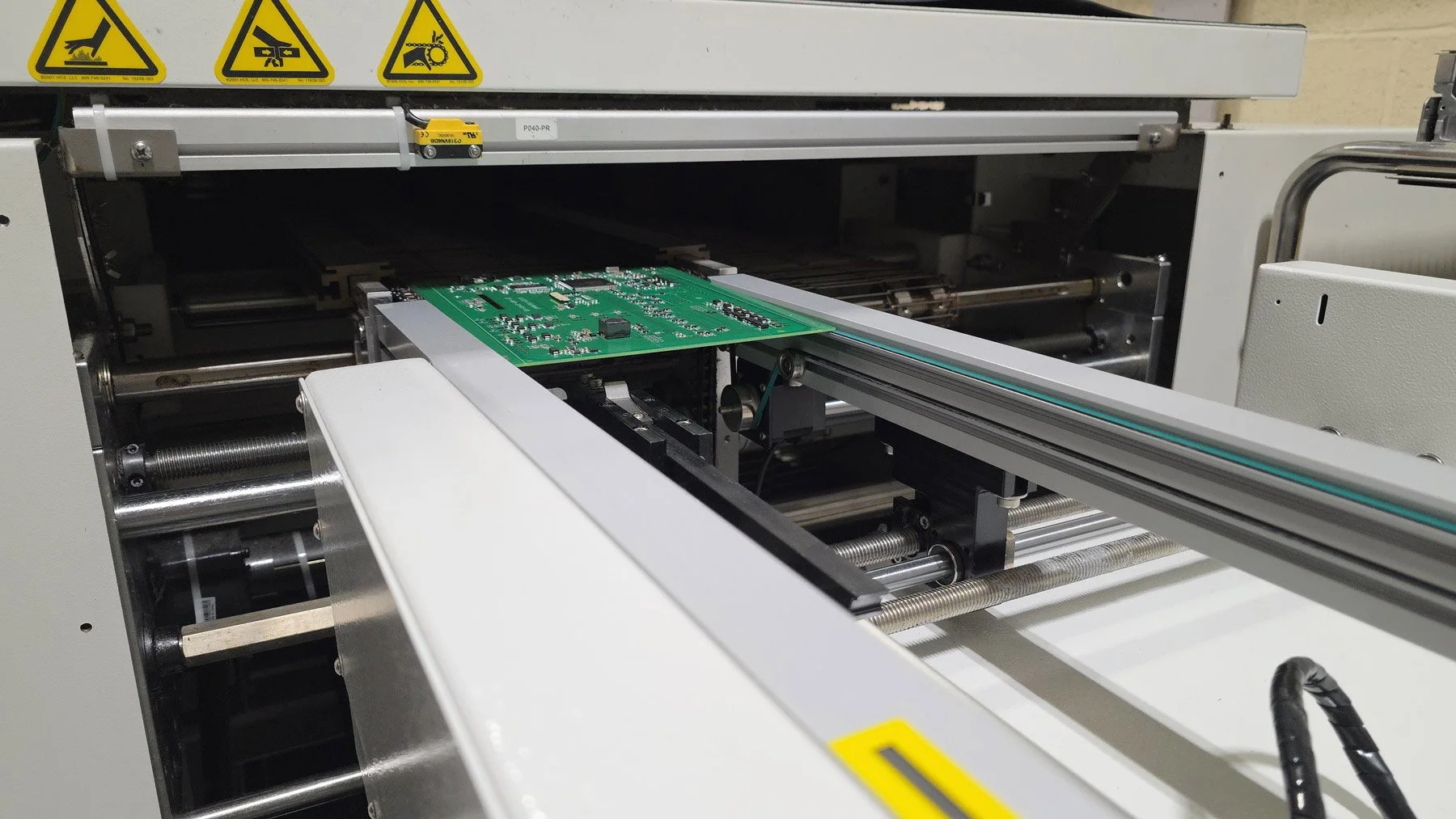

Next, our automated surface mount technology machines (pick-and-place systems) position each component with pinpoint accuracy. Whether it’s a standard capacitor or a micro surface mount device LED, every placement meets exacting tolerances.

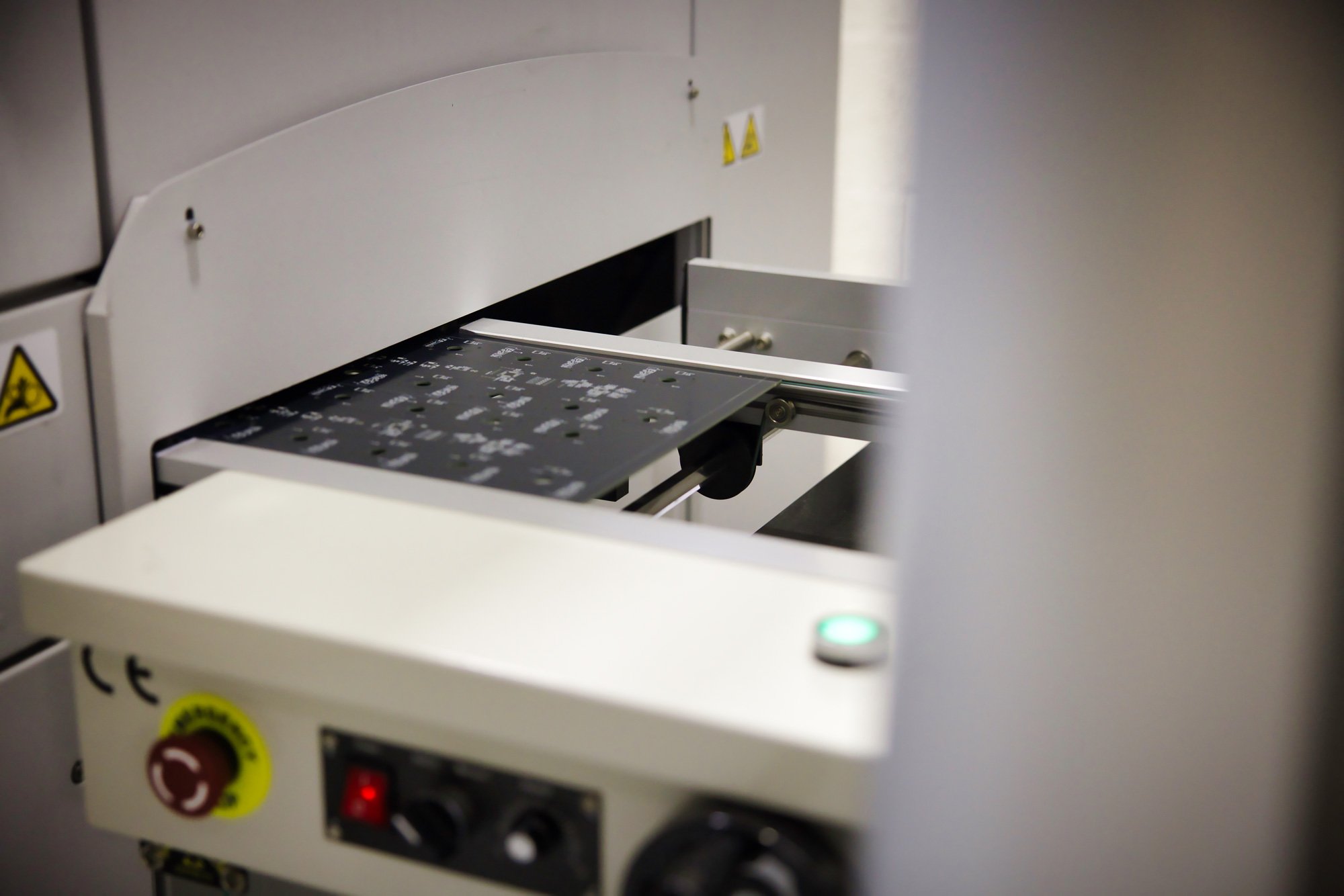

3. Reflow Soldering Process

Once positioned, boards pass through a reflow soldering process where controlled heat melts and re-solidifies the solder. This ensures robust electrical connections. For complex assemblies, we use double-sided PCB reflow, allowing components on both sides of the board to be bonded without compromising quality.

Precision is key throughout. Our expertise in soldering and surface mount technology ensures optimal temperature control, perfect solder joints, and fault-free performance, whether in surface mount reflow or hybrid assembly involving through-hole components.

Surface Mount Technology Equipment and Quality Assurance

We invest in leading surface mount technology equipment to maintain efficiency and accuracy throughout production. Our facilities feature:

Stencil printers for uniform solder paste application

Pick-and-place machines capable of ultra-fine component alignment

Reflow ovens for stable and consistent reflow processes

Automated inspection tools including AOI and X-ray systems

For projects that integrate both SMT and through-hole components, flow soldering is used to complete hybrid builds without compromising quality.

Every board undergoes rigorous quality checks to ensure durability, reliability, and full compliance with client specifications. We are proud of our reputation for delivering assemblies that meet strict performance standards across a range of industries.

Applications and Industry Expertise

Our surface mount assembly services are trusted across multiple sectors including automotive, industrial, and consumer electronics. From LED SMD PCBs to compact control boards, we deliver solutions that combine precision with scalability.

Surface mount device soldering offers unmatched advantages in miniaturisation and performance, making it the preferred choice for modern manufacturing. With First Choice Assembly, you benefit from advanced mount technology, fast turnaround times, and exceptional customer support at every stage of your project.

Partner with First Choice Assembly

For dependable, high-precision PCB assembly services, partner with a team that understands your production goals. At First Choice Assembly, we bring decades of experience in surface mount technology soldering and PCB manufacturing to every project.

Contact us today to discuss your assembly requirements and request a bespoke quotation. Call us 01384 891 991

Get a Quote

Interested in our surface mount assembly services?

Get in touch with our team and we can supply a detailed quote for your project requirements.

Contact

Why choose FCA?

From concept to completion

At First Choice Assembly, we support your project every step of the way. Our skilled team collaborates with you to transform initial ideas into detailed designs, ensuring each PCB meets precise specifications. We handle material sourcing, prototyping, and full-scale assembly in-house, guaranteeing quality and efficiency at every stage.

With rigorous testing and lifetime assurance on all products, we deliver reliable solutions that meet industry standards and bring your vision to life.

Full Turnkey Solutions

First Choice Assembly offers complete end-to-end PCB solutions, handling everything from design and sourcing to assembly, ensuring a seamless, efficient process for clients.

Bespoke Design In-House

First Choice Assembly’s expert team provides custom PCB designs tailored to unique project specifications, bringing flexibility and precision to every build.

Lifetime Assurance

Our commitment to value is backed by a lifetime warranty against manufacturing defects. Underscoring our commitment to quality and providing long-term reliability for all manufactured products.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors.