Why Sourcing Your PCB Assembly in the UK is the Strategic Move for 2025

For the last two decades, the electronics manufacturing industry operated under a singular, dominant assumption: to be competitive, you had to manufacture offshore. Procurement managers and product designers were conditioned to chase the lowest possible unit price, often looking to East Asia to shave pennies off the Bill of Materials (BOM).

However, as we move through 2025, the global landscape has shifted dramatically. Volatile shipping costs, geopolitical instability, and the increasing complexity of electronic designs have exposed the fragility of long-distance supply chains. The "cheapest" option on paper is frequently becoming the most expensive option in practice.

For UK businesses, the conversation is no longer about "outsourcing"; it is about "reshoring." Strategic sourcing is returning home, and PCB Assembly is at the heart of this transition. Here is why switching your assembly to a UK-based partner like First Choice Assembly is the smartest move for your bottom line and your brand reputation.

The "Hidden Costs" of Offshore Manufacturing

When you look at a quote from an overseas supplier, you are often looking at the "ex-works" price, the cost of the board as it leaves the factory door. You aren't seeing the Total Cost of Ownership. When you rely on offshore vendors for your PCB Assembly, you introduce variables that are difficult to control and expensive to mitigate.

Logistics and Customs Friction

While freight costs fluctuate, the time lost in customs is a constant risk. Post-Brexit import regulations have added layers of administrative complexity to importing assembled electronics. A batch of boards stuck in customs for five days can derail a product launch or force you to miss a critical client deadline. Local sourcing eliminates the customs headache entirely.The "Cost of Quality"

Imagine waiting six weeks for a shipment of 1,000 boards, only to discover a 5% failure rate due to a misunderstanding of the soldering specification. You cannot simply drive down the road to resolve it. You are faced with the cost of rework, the cost of shipping returns, and the reputational damage of delaying delivery to your own customers.The "Cost of Quality"

Imagine waiting six weeks for a shipment of 1,000 boards, only to discover a 5% failure rate due to a misunderstanding of the soldering specification. You cannot simply drive down the road to resolve it. You are faced with the cost of rework, the cost of shipping returns, and the reputational damage of delaying delivery to your own customers.

Agility: The New Currency of Electronics

In 2025, the market rewards agility over raw volume. Product lifecycles are shorter, and revisions are more frequent.

If you are developing a new IoT device or a control panel, your design will likely evolve. Managing Engineering Change Notes (ECNs) with a factory 5,000 miles away is a logistical nightmare. By the time the message filters down to the shop floor, the wrong boards may have already been populated.

When you choose a UK partner for your PCB Assembly, you gain the ability to pivot. At First Choice Assembly, our location in the West Midlands places us at the logistics heart of the country. We can pause, adjust, and implement design changes almost instantly. This agility allows our clients to prototype faster, iterate more effectively, and get to market months ahead of competitors who are waiting for shipping containers.

Supply Chain Security and Traceability

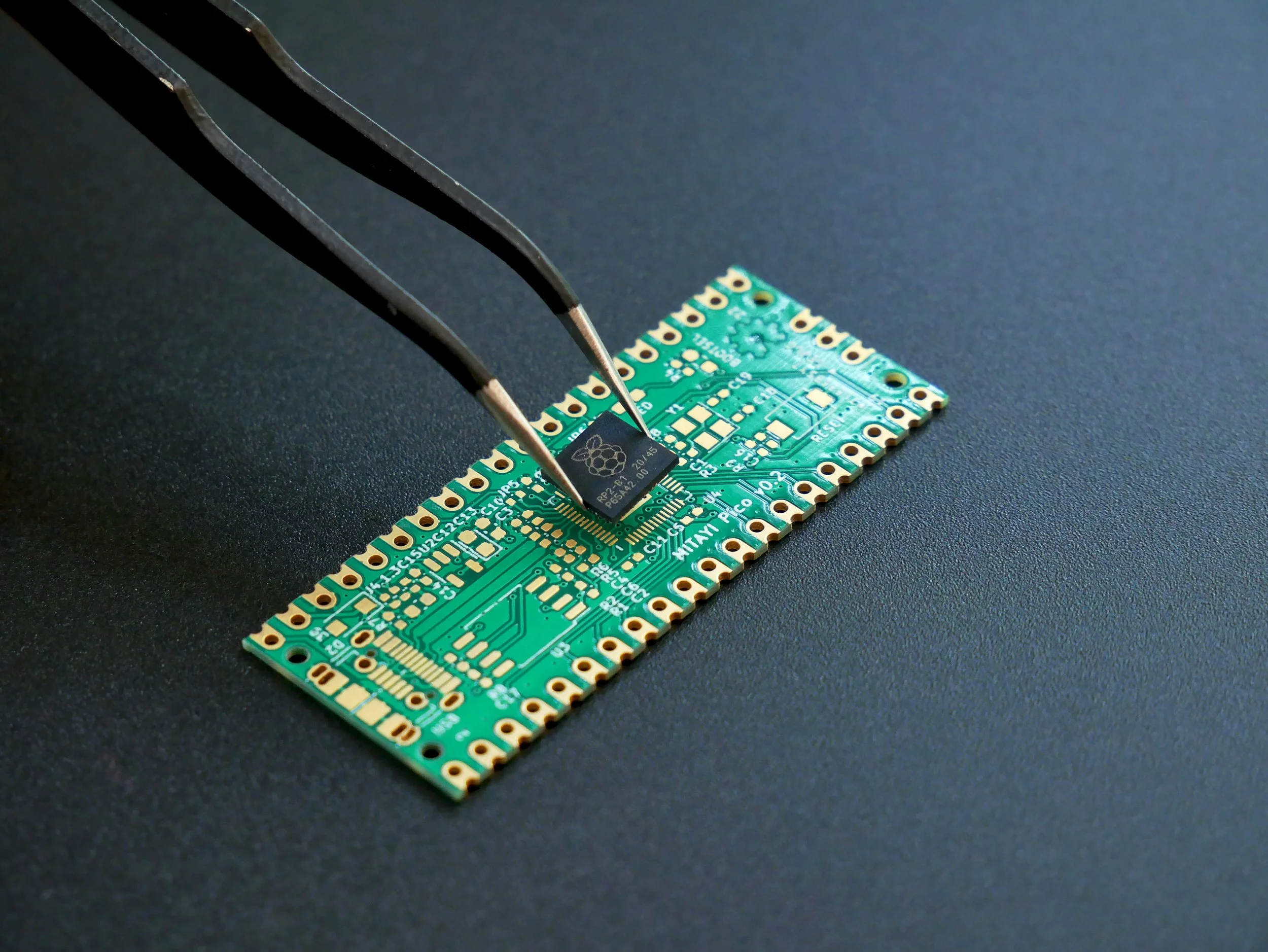

One of the growing concerns in the electronics sector is the infiltration of counterfeit components into the supply chain. High-value chips and processors are often targets for grey-market substitutions, which can compromise the safety and longevity of your final product.

UK-based assemblers operate under stringent regulatory frameworks. At First Choice Assembly, we prioritise traceability. We source from authorised distributors and verified channels. Because we are local, you have full visibility. You aren't just sending a file into a "black box"; you are engaging with a transparent process where you know exactly where your components are coming from.

The Ultimate Trust Signal: Lifetime Assurance

Perhaps the most significant difference between First Choice Assembly and both offshore and domestic competitors is our confidence in our workmanship.

Browse the websites of most electronics manufacturers, and you will see standard warranty terms usually 12 months. They expect their boards to last, but they financially limit their liability.

We take a different approach. We offer a unique Lifetime Assurance on our assembly workmanship.

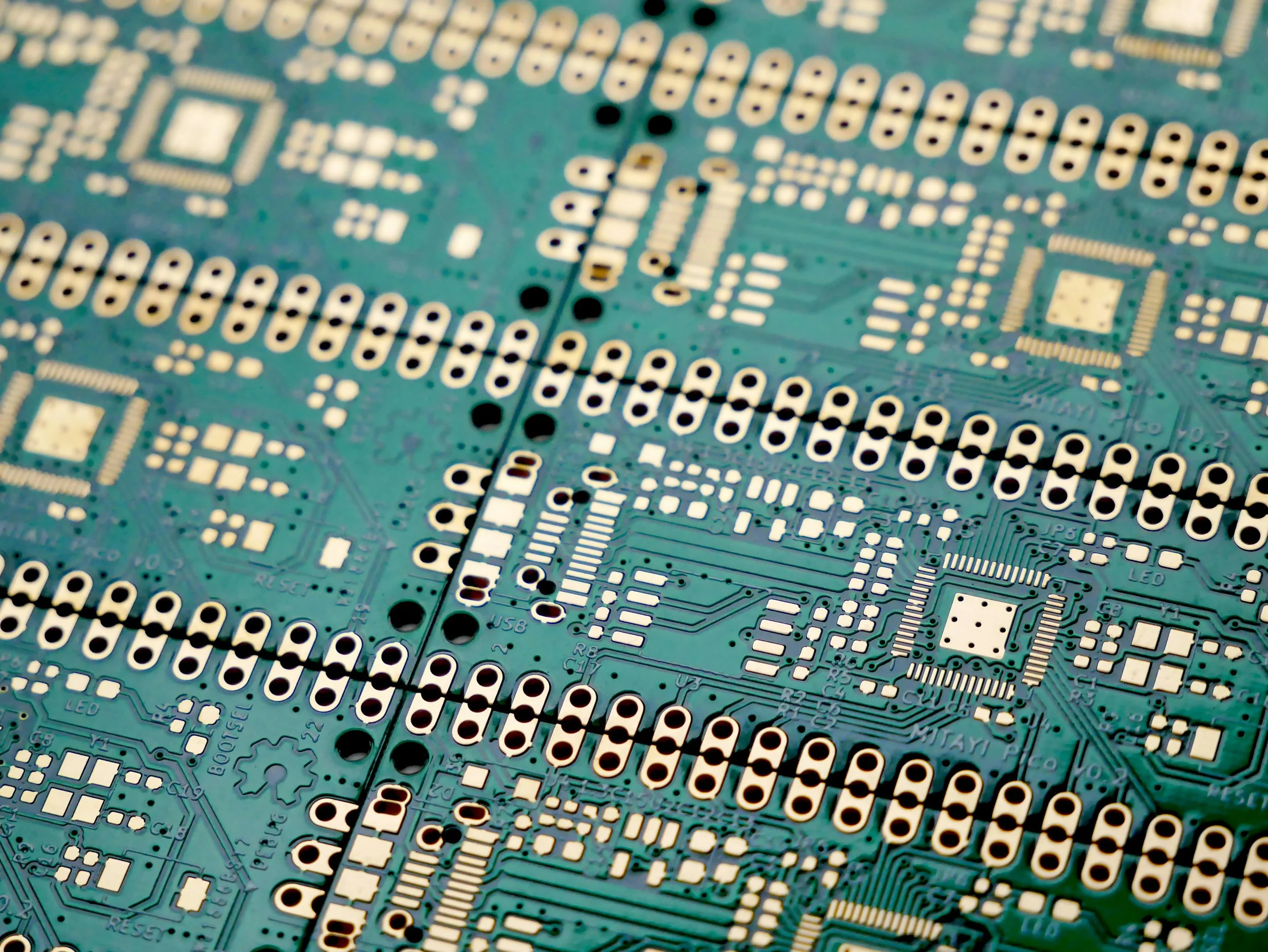

Why do we do this? Because our PCB Assembly process combines state-of-the-art Surface Mount Technology (SMT) with rigorous Automated Optical Inspection (AOI) and expert human oversight. We don't just "stuff boards"; we engineer reliability.

If a solder joint fractures due to poor workmanship? We fix it.

If a component is placed incorrectly? We rectify it.

This level of guarantee is rare in the industry. It transforms your manufacturing spend from a gamble into an investment. It signals to your stakeholders that you are prioritising quality above all else.

Value Over Price

The era of chasing the lowest invoice price is ending. Today, successful procurement is about securing a supply chain that is resilient, transparent, and responsive.

By moving your PCB Assembly to First Choice Assembly, you aren't just buying a populated circuit board. You are buying the security of a UK partner, the speed of local logistics, and the peace of mind that comes with a Lifetime Assurance.

Don't let supply chain distance compromise your product quality.

Are you ready to secure your production line? Visit our PCB Assembly page today to explore our capabilities and request a quote.