Choosing the Right PCB Assembly Partner

Selecting the right PCB assembly partner can save time, reduce errors, and improve product quality. This page provides guidance on evaluating potential suppliers, highlighting the expertise, certifications, and customer service factors that make First Choice Assembly a trusted UK partner.

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

1. What should I look for in a PCB assembly company?

Look for experience, industry certifications, and a proven track record of delivering high-quality PCBs. Expertise in both SMT and through-hole assembly ensures they can handle a variety of projects.

Also consider their customer support, flexibility for prototypes and production runs, and ability to meet lead times reliably. A good assembler should act as a partner, not just a supplier.

2. How does First Choice Assembly demonstrate expertise?

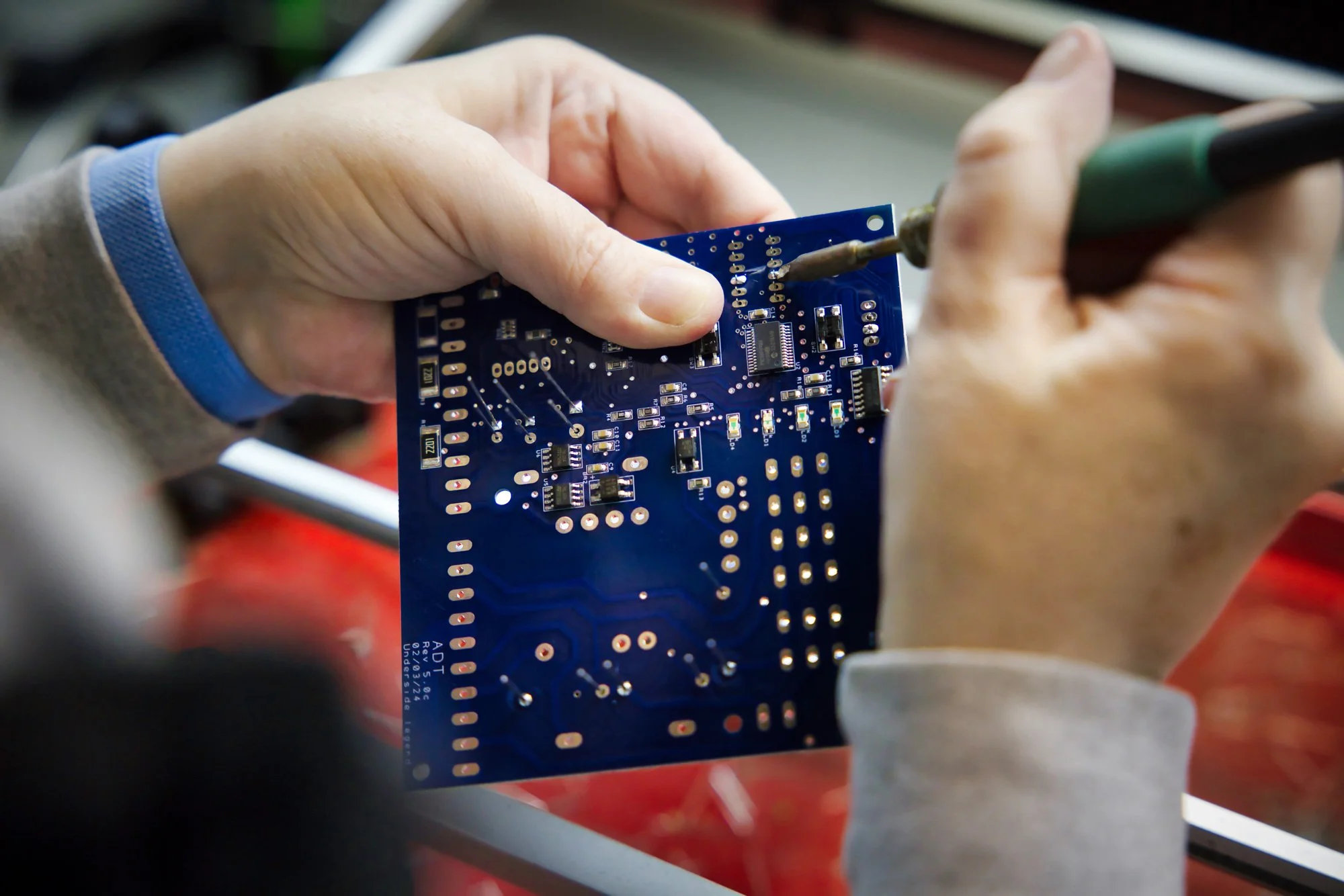

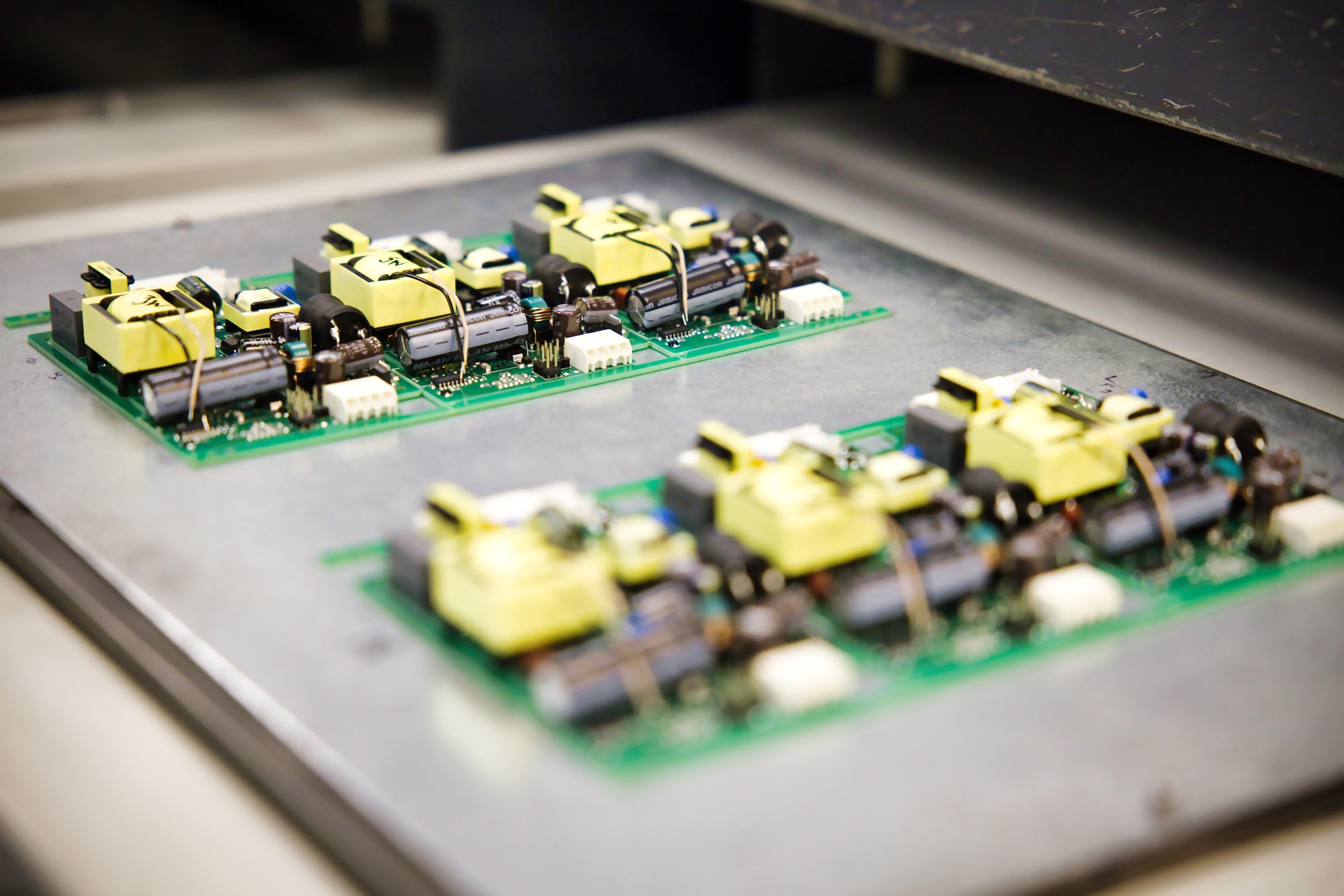

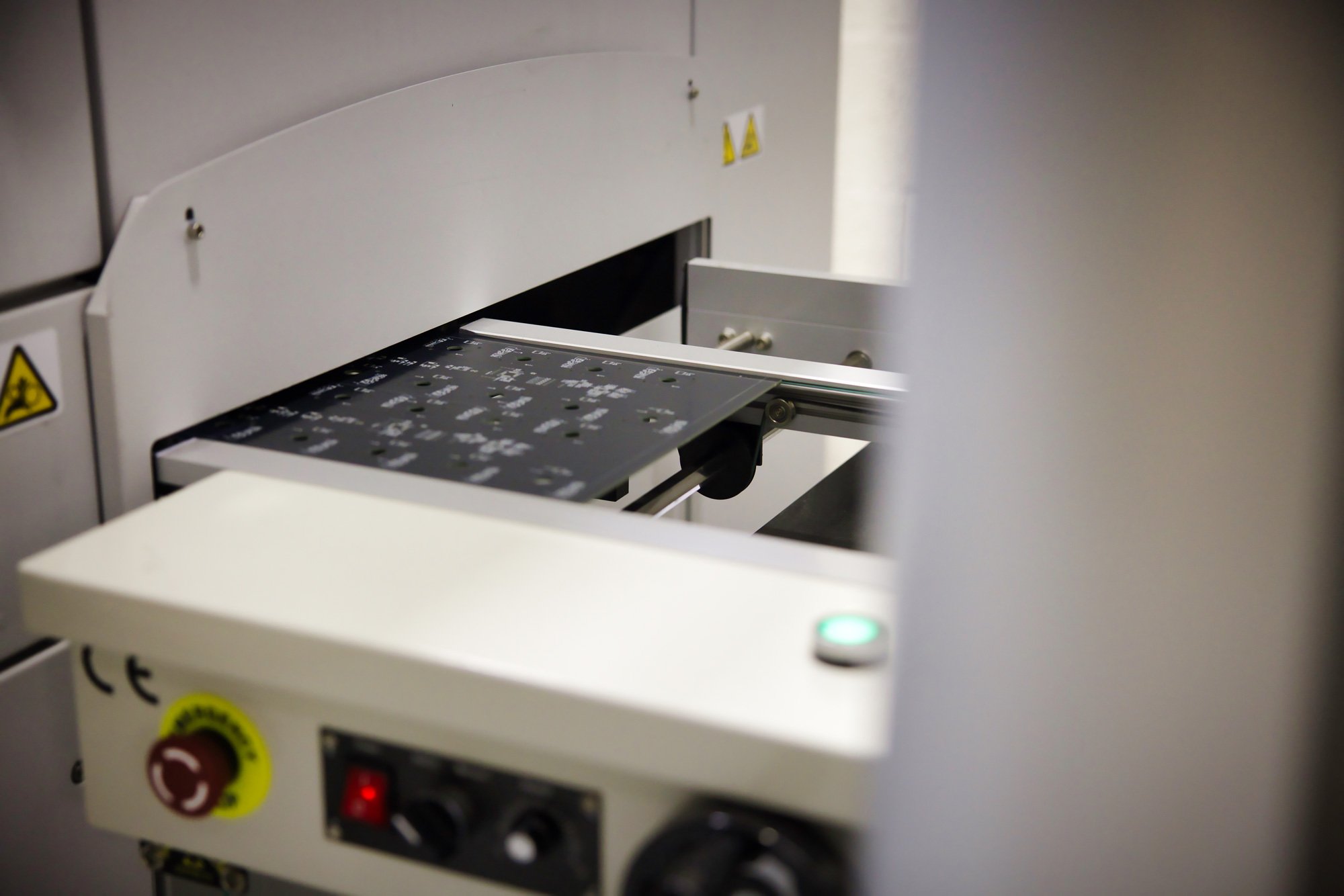

First Choice Assembly demonstrates expertise through ISO-certified processes, skilled technicians, and advanced assembly equipment. We handle complex boards and high-density assemblies for diverse industries.

Case studies, client testimonials, and consistent delivery of high-quality boards reinforce our technical knowledge and experience. Our team’s proficiency ensures reliable and efficient assembly every time.

3. What makes a PCB assembler trustworthy?

Trustworthiness comes from transparency, certifications, quality assurance, and consistent delivery. A reliable assembler communicates clearly and adheres to deadlines and specifications.

Using verified components, following industry standards, and providing thorough testing also builds confidence. Trust is earned by consistently delivering reliable, compliant, and functional PCBs.

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

4. Are reviews and case studies important?

Yes, reviews and case studies provide insight into the assembler’s experience and reliability. They demonstrate real-world performance and the ability to meet client expectations.

They also show how issues are handled and the level of support provided. Positive feedback from other UK businesses builds confidence in the company’s capabilities.

5. How do I compare UK assembly providers?

Compare providers based on experience, range of services, certifications, and pricing transparency. Evaluate their capability to handle your specific PCB types and production volumes.

Also consider quality assurance processes, lead times, and communication. Choosing a provider with a proven local track record helps reduce risk and ensures reliability.

6. What questions should I ask before outsourcing PCB assembly?

Ask about certifications, experience with similar boards, quality control procedures, and lead times. Inquire about component sourcing, testing, and rework capabilities.

Clarify pricing, minimum order quantities, and support for prototypes. These questions help ensure the provider aligns with your technical and commercial requirements.

7. How do lead times affect my project?

Lead times impact when your product can reach the market and influence development schedules. Longer lead times can delay prototypes, testing, and production launch.

Choosing a UK assembler with efficient processes and reliable supply chains helps meet deadlines and reduce risk. Proper planning ensures timelines are achievable without compromising quality.

8. What guarantees or warranties should I expect?

Assemblers typically provide warranties covering workmanship and component installation. This ensures that any assembly defects discovered within the warranty period are rectified at no additional cost.

Guarantees reinforce confidence in reliability and encourage trust between the client and assembler. They demonstrate the provider’s commitment to quality and accountability.

9. How does FCA support prototypes and production?

First Choice Assembly supports both prototypes and full production runs with flexible processes and expert guidance. We can advise on design, component selection, and assembly methods to ensure success.

Our team ensures quality and reliability at every stage, from low-volume prototypes to high-volume production. This support helps clients reduce errors, accelerate timelines, and achieve high-quality results.

10. What warranty is provided on reworked boards?

Reworked boards are typically covered by a warranty that guarantees the repair work and component replacement. This gives clients confidence that the boards will perform as intended.

The exact terms of the warranty depend on the scope of the rework and the components involved. First Choice Assembly ensures clear communication and support for all repaired boards.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors