Introduction to PCB Assembly

Printed circuit board (PCB) assembly is a critical step in turning an electronic design into a fully functioning device. This page introduces the key concepts of PCB assembly, explains the different types of PCBs, and highlights why choosing a reliable UK assembler like First Choice Assembly can make all the difference for both prototypes and production runs.

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

1. What is printed circuit board (PCB) assembly?

PCB assembly is the process of attaching electronic components to a printed circuit board to create a functional electronic device. It combines precision soldering, component placement, and quality control to ensure the board operates correctly.

The assembly process can include surface mount technology (SMT), through-hole assembly, or a combination of both, depending on the design and functionality of the PCB. Professional assembly ensures consistency, reliability, and efficiency for prototypes and production runs.

2. What are the main types of PCBs used in UK electronics?

The most common types of PCBs in the UK are single-sided, double-sided, and multi-layer boards, each varying in complexity and application. Multi-layer PCBs are widely used for advanced electronics where space and performance are critical.

Other variations include flexible PCBs for wearable technology and rigid-flex boards for applications requiring both flexibility and durability. The choice of PCB type depends on the device’s design, function, and production requirements.

3. How does PCB assembly differ from PCB manufacturing?

PCB manufacturing focuses on producing the bare circuit board, including the copper traces, insulation layers, and drilled holes. It does not include mounting or soldering the electronic components.

PCB assembly, on the other hand, involves populating the manufactured boards with components, testing, and preparing them for functional use. Assembly transforms a manufactured board into a working electronic device ready for integration.

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

4. Why is high-quality PCB assembly important?

High-quality PCB assembly ensures electronic devices operate reliably, safely, and efficiently, reducing the risk of failures. It also improves product lifespan and customer satisfaction.

Poor assembly can lead to faults, component damage, or total device failure, increasing costs through repairs and recalls. Investing in expert assembly minimises these risks and maintains the integrity of the product.

5. What industries use PCB assembly services in the UK?

PCB assembly services support a wide range of UK industries, including medical devices, automotive electronics, consumer electronics, and industrial machinery. Each sector relies on precise, reliable assembly to meet stringent performance and safety standards.

Other industries include aerospace, telecommunications, and energy, where complex or high-performance boards are essential. The versatility of PCB assembly makes it critical for almost every modern electronics application.

6. How do I choose a PCB assembly company?

Choose a PCB assembly company with proven experience, quality certifications, and a portfolio of successful projects. Reputation, technical capability, and customer support are key factors in selecting a reliable partner.

It is also important to consider the company’s capacity for prototypes and production runs, as well as their ability to source high-quality components efficiently. UK-based providers offer advantages in communication, lead times, flexibility and compliance with local regulations.

7. What is the difference between prototype and production PCB assembly?

Prototype PCB assembly focuses on small runs for testing and validation, allowing design tweaks before full production. It prioritises flexibility, speed, and accuracy in evaluating new designs.

Production PCB assembly involves large-scale manufacturing, often using automated lines to maintain consistent quality and efficiency. The focus is on cost-effective, high-volume output while maintaining reliability and compliance.

8. How does PCB assembly impact product reliability?

Accurate and high-quality PCB assembly directly affects the functionality and durability of an electronic device. Correct soldering, component placement, and inspection minimise faults and ensure consistent performance.

Poor assembly can cause intermittent failures, reduced lifespan, or safety hazards, undermining customer trust. Professional assembly provides confidence that the product will operate as designed under real-world conditions.

9. Can PCB assembly be outsourced in the UK?

Yes, many UK businesses outsource PCB assembly to specialist providers to access expertise, reduce costs, and speed up production. Local providers offer advantages in lead times, quality control, flexibility and compliance with UK standards.

Outsourcing allows companies to focus on design and development while leaving the complex assembly, testing, and supply chain management to experienced professionals. It is a common practice across industries seeking high-quality, reliable PCBs.

10. How long does PCB assembly usually take?

PCB assembly timelines vary depending on complexity, volume, and component availability. Simple prototype boards may be completed within days, while full production runs can take several weeks.

Efficient supply chain management and experienced assembly providers can significantly reduce lead times. Planning ahead and communicating clearly with your assembler ensures schedules are met without compromising quality.

11. What are the processes involved within PCB Assembly?

A: Solder Paste Application

A stencil is used to apply solder paste (a mix of tiny solder particles and flux) to the pads where components will sit.

B: Pick and Place

Automated machines place surface-mount components (SMDs) onto the board with high precision.

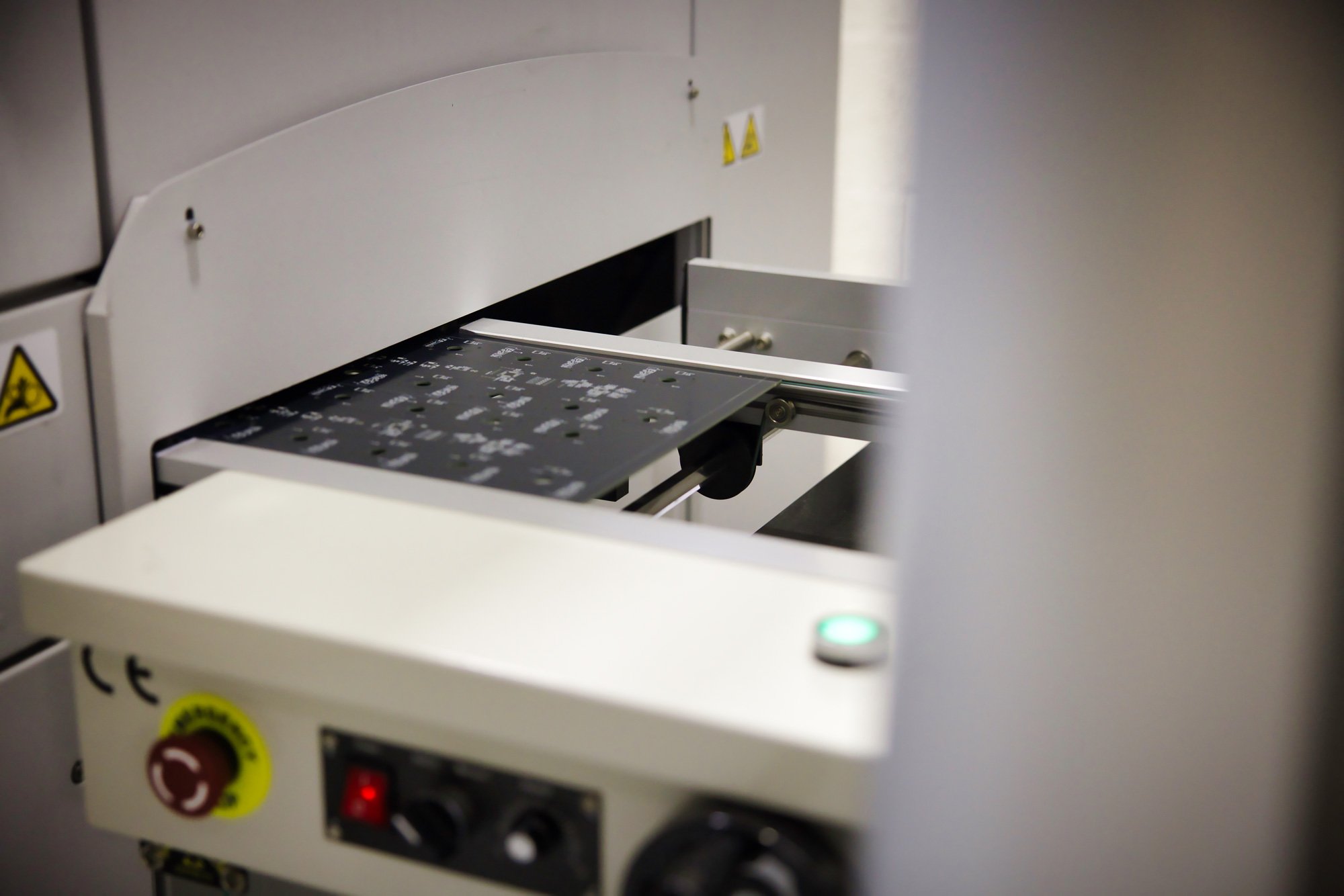

C: Reflow Soldering

The board is passed through a reflow oven, melting the solder paste and securing the components.

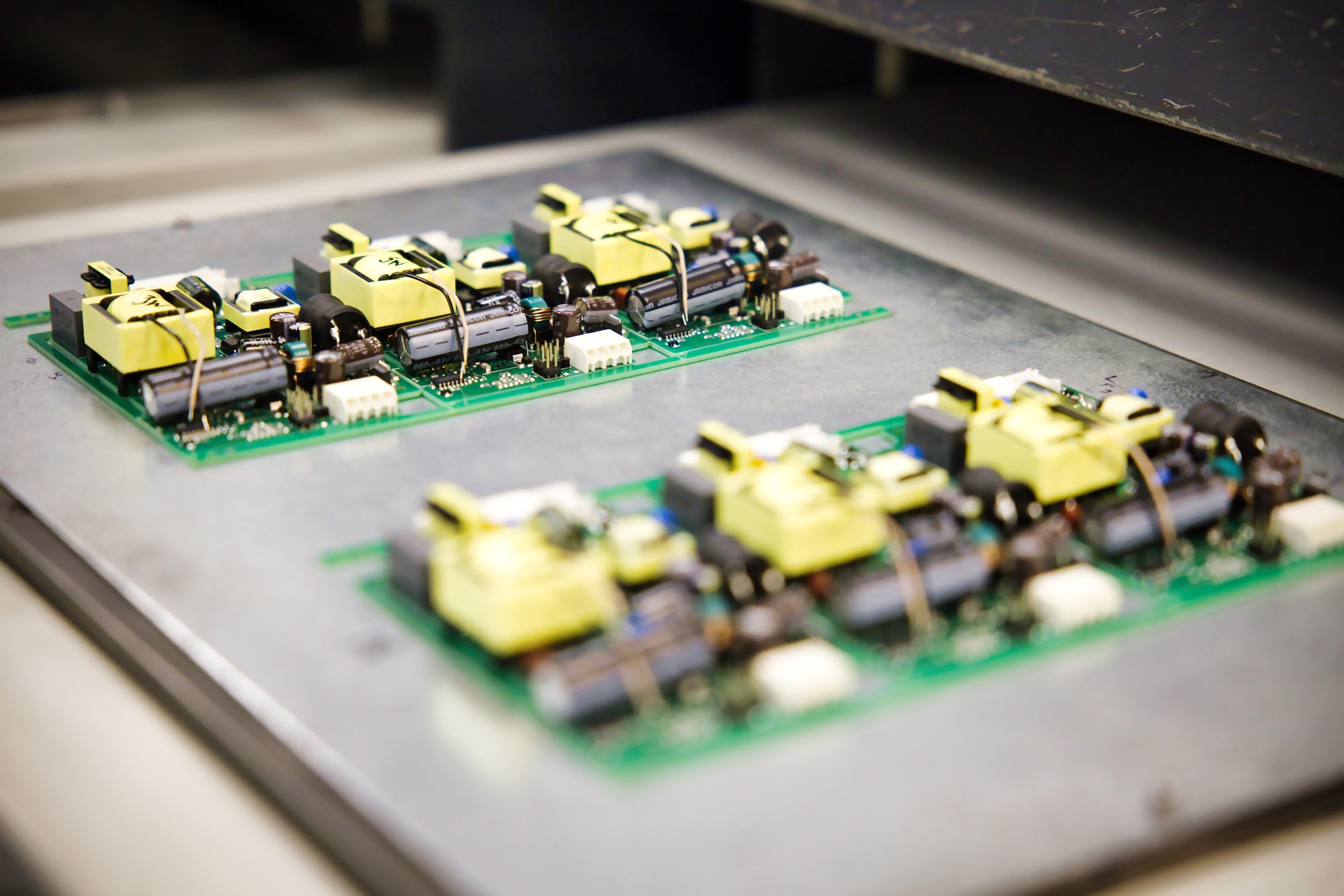

D: Through-Hole Component Insertion

For components with leads that go through the board, these are inserted manually or by machine.

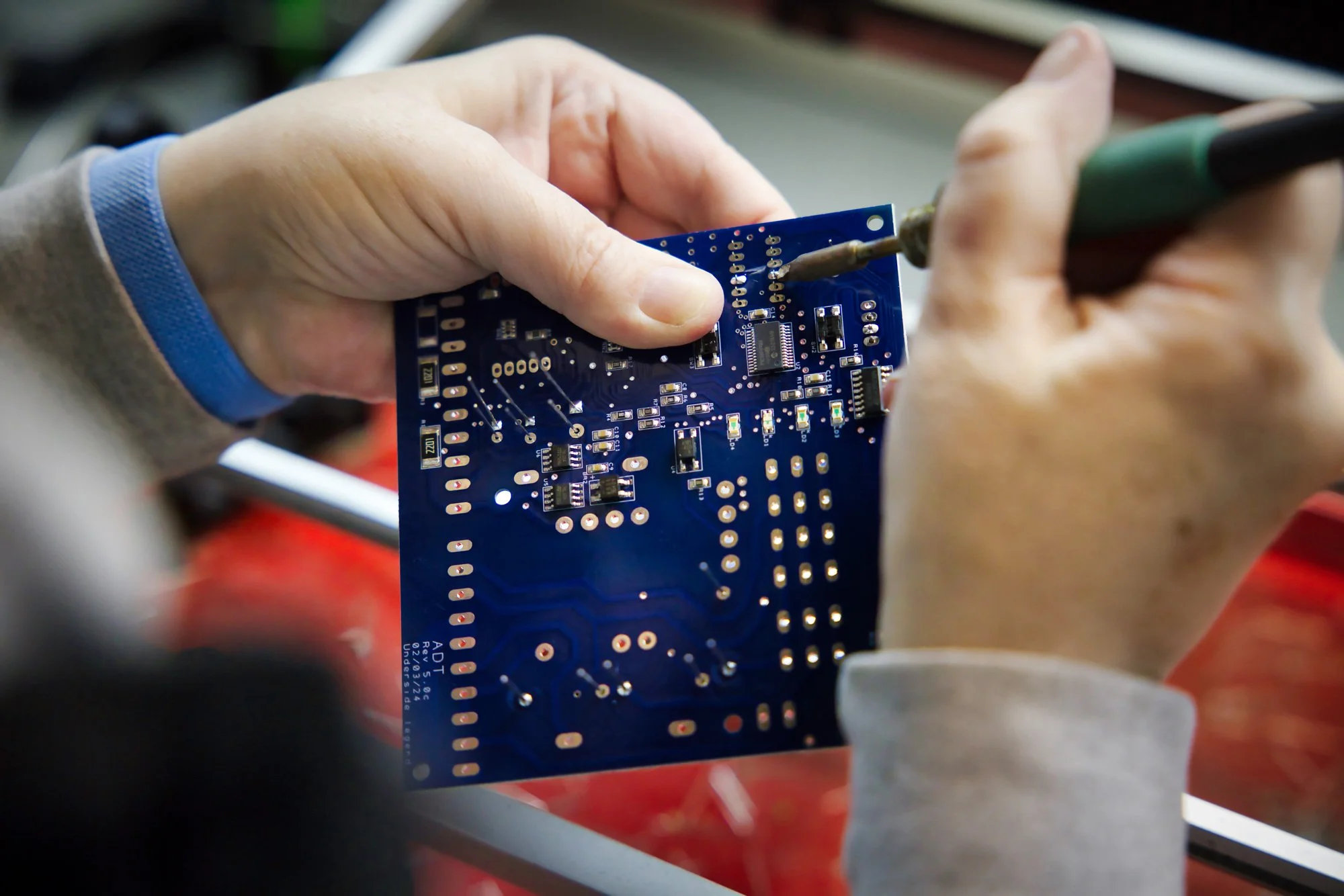

E: Wave Soldering or Hand Soldering

Through-hole components are soldered, often using a wave soldering machine or by hand.

F: Inspection and Testing

Visual inspection, automated optical inspection (AOI), X-ray inspection, and functional testing ensure quality and performance.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors