Surface Mount Technology (SMT) Assembly

Surface mount technology (SMT) allows components to be mounted directly onto the surface of a PCB, enabling smaller, more complex, and higher-performance boards. This page explores the benefits of SMT, the types of components commonly used, and how modern automated assembly techniques ensure precision and reliability.

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

1. What is surface mount technology (SMT)?

Surface mount technology (SMT) is a method of attaching electronic components directly onto the surface of a printed circuit board rather than inserting leads through holes. It allows for smaller, more complex, and higher-density circuit designs.

SMT is widely used in modern electronics because it supports faster assembly, reduces material costs, and enables automated production processes. Components are precisely placed and soldered using advanced machinery to ensure reliability.

2. What are the advantages of SMT over through-hole assembly?

SMT allows for smaller, lighter, and more compact electronic designs compared with through-hole assembly. It also supports higher component density, making it ideal for modern high-performance devices.

Additionally, SMT is well-suited for automation, which increases production speed and consistency while reducing labour costs. It also improves electrical performance due to shorter lead lengths and reduced parasitic effects.

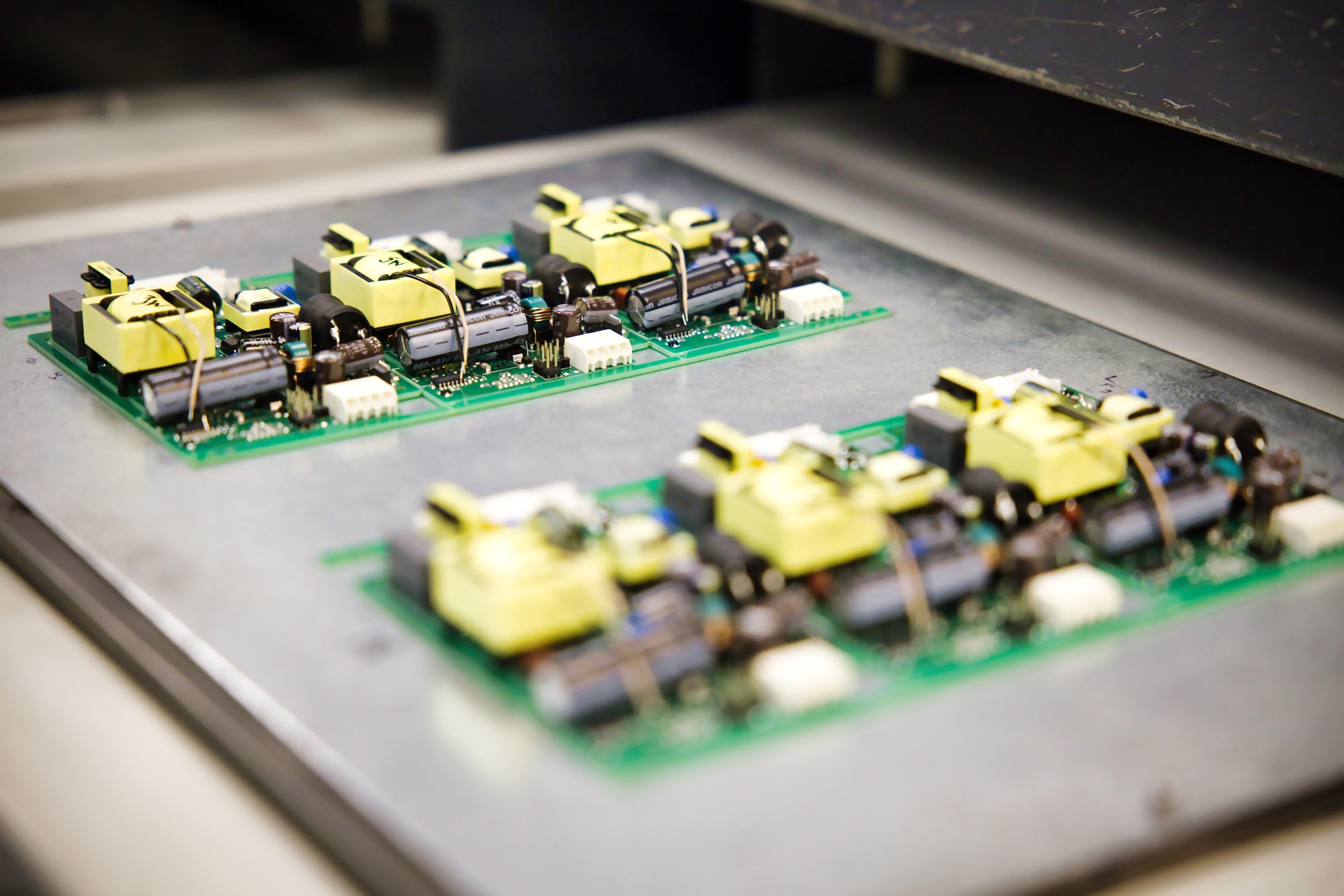

3. Which components are commonly used in SMT assembly?

Common SMT components include resistors, capacitors, diodes, transistors, integrated circuits (ICs), and LEDs. These components are designed with flat or gull-wing leads suitable for surface mounting.

Other specialised components, such as microcontrollers and small sensors, are also used in SMT to enable compact, multi-functional PCBs. The choice of components depends on the device’s requirements and design complexity.

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

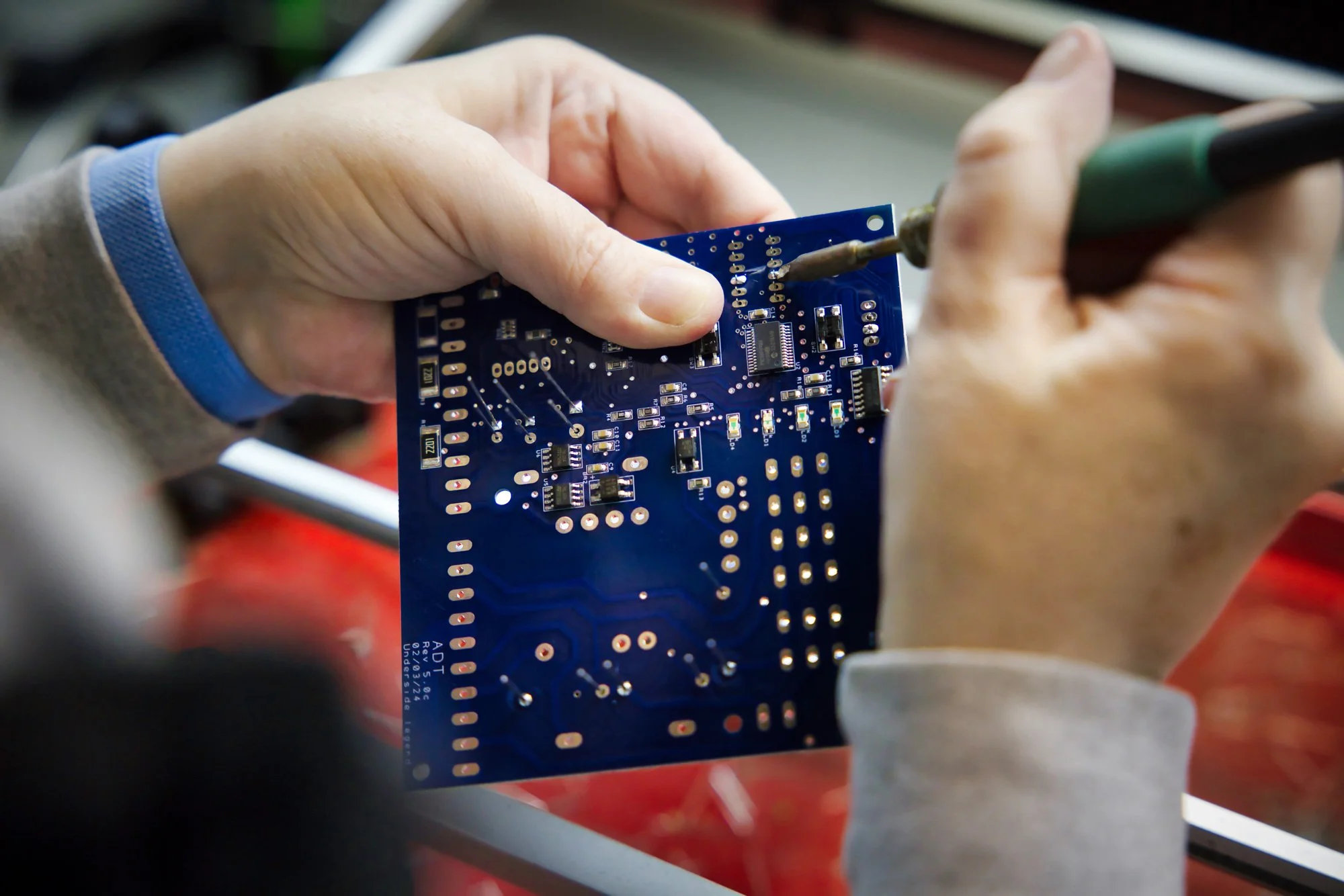

4. How precise is SMT placement?

SMT placement is extremely precise, typically accurate to fractions of a millimetre. Automated pick-and-place machines position each component exactly where it is required on the PCB.

Precision is critical for high-density boards, where small errors can lead to short circuits, signal issues, or device failure. Advanced vision systems ensure correct alignment and orientation during placement.

5. Can SMT be used for small-scale production?

Yes, SMT can be used for small-scale production, including prototypes and low-volume batches. Many UK providers offer flexible runs that accommodate smaller projects without compromising quality.

While automated processes are most cost-effective for larger volumes, modern assembly equipment allows efficient small-scale production with fast turnaround. This ensures new designs can be tested quickly before full-scale manufacturing.

6. What are common SMT defects and how are they prevented?

Common SMT defects include solder bridging, tombstoning, component misalignment, and insufficient solder. These defects can occur due to incorrect solder paste application, poor placement, or temperature issues during reflow.

Prevention relies on accurate solder paste printing, precise pick-and-place machines, and controlled reflow processes. Inspection and testing further ensure that defects are identified and corrected before boards leave the facility.

7. How does solder paste work in SMT assembly?

Solder paste is a mixture of powdered solder and flux applied to PCB pads before component placement. It temporarily holds components in place and forms the permanent solder joints during reflow.

During reflow soldering, the paste melts and solidifies to create strong electrical and mechanical connections. Proper paste application and consistent thickness are essential for reliable assembly.

8. How are SMT boards inspected for quality?

SMT boards are inspected using automated optical inspection (AOI), X-ray inspection, and functional testing. These methods detect misalignment, solder defects, missing components, and other assembly issues.

Quality inspection ensures that only boards meeting stringent specifications move forward to testing or delivery. This reduces the risk of failures in the field and maintains high reliability standards.

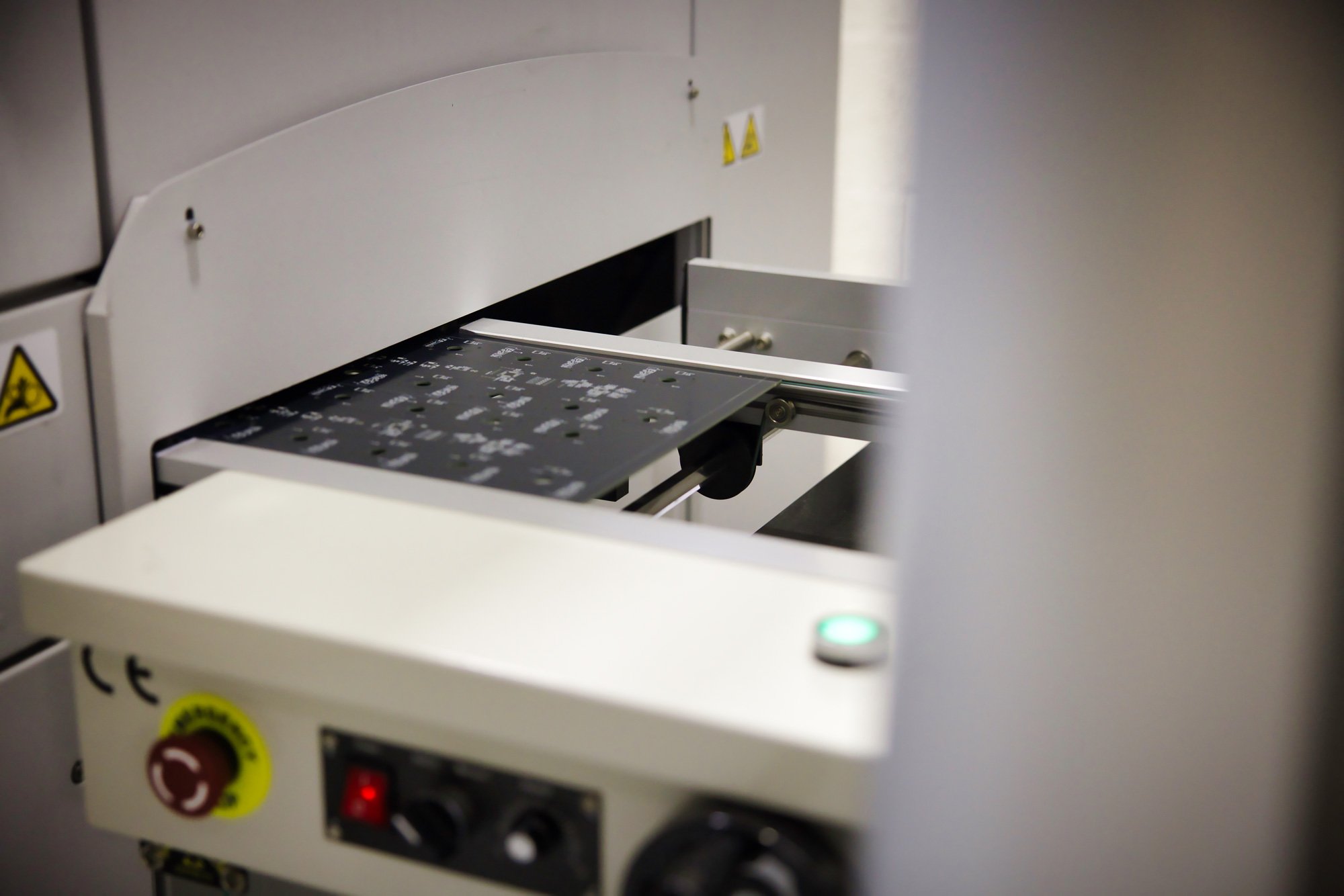

9. Can SMT assembly be automated in the UK?

Yes, SMT assembly in the UK is commonly automated using pick-and-place machines, solder paste printers, and reflow ovens. Automation improves precision, efficiency, and consistency across production runs.

Automated assembly also allows UK manufacturers to scale production while maintaining quality and meeting tight lead times. Skilled operators oversee the process and handle any exceptions manually.

10. What is reflow soldering in SMT?

Reflow soldering is the process of heating a PCB with solder paste to melt the solder and form permanent joints between components and pads. It is the standard soldering method for SMT assembly.

Controlled heating profiles ensure proper melting and solidification without damaging components. Reflow soldering is highly reliable and compatible with high-volume automated assembly lines.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors