Mastering the PCB Assembly Process: A Comprehensive Guide

Precision is the cornerstone of every successful PCB assembly process. At First Choice Assembly, we combine years of technical expertise with cutting-edge technology. Our team ensures that your designs transition from a concept to a high-quality physical product. As a leading PCB making company, we understand the complexities of modern electronics. We refine every stage of the printed circuit board assembly process to guarantee reliability. Our commitment to excellence makes us the preferred partner for businesses across the United Kingdom. We focus on quality, speed, and meticulous attention to detail.

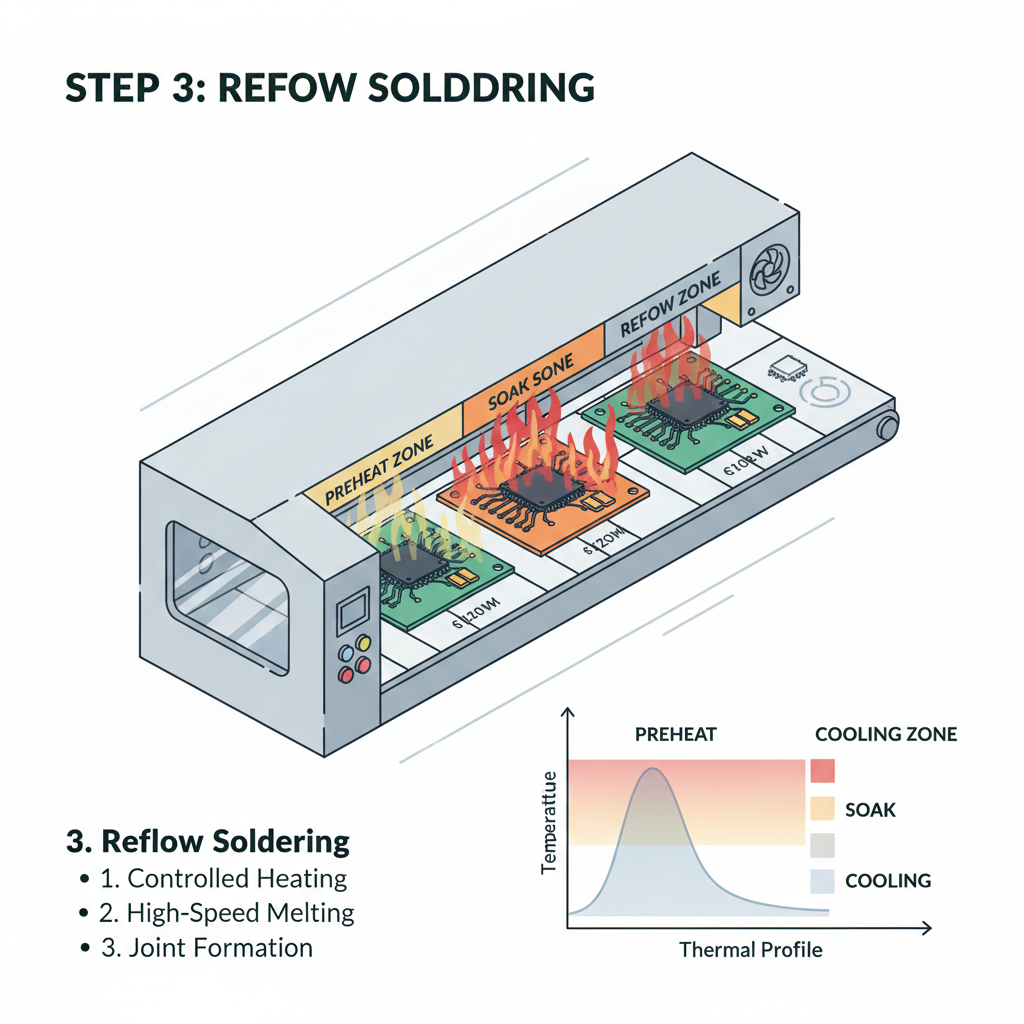

An Overview of the PCB Manufacturing Process Flow

Efficiency in production begins with a well-defined PCB manufacturing process flow. This structured approach ensures that every component is placed with absolute accuracy. The journey begins with a thorough review of your design files. We check for potential issues before the PCB board assembly process even starts. This proactive method prevents costly errors and ensures a smooth assembly line flow during production.

Our facility is equipped to handle the entire PCB manufacturing cycle in-house. By maintaining control over every stage, we offer a level of consistency that few can match. This holistic view of the industrial PCB manufacturing process allows us to scale production according to your specific needs. Whether you require a small batch of prototypes or a large production run, our systems remain robust.

Understanding the PCB Manufacturing Steps

The PCB manufacturing steps we follow are designed to meet rigorous British standards. Every stage is a vital link in the chain of quality, ensuring meticulous detail and precision.

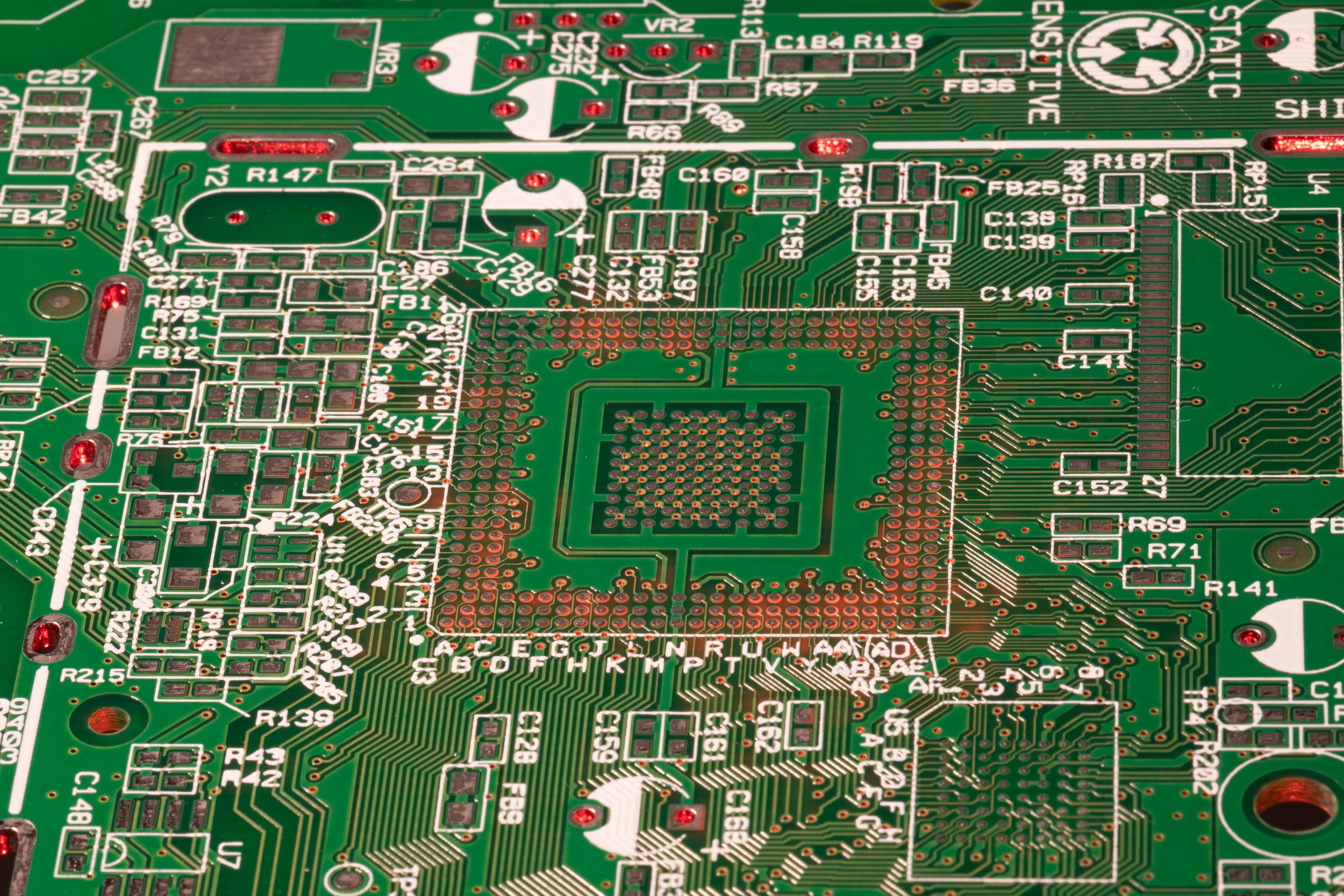

Step 1: Solder Paste Application

The first critical stage involves applying a precise amount of solder paste. Using a high-quality stencil, we ensure that the paste is deposited only onto the designated pads where components will be placed. This accuracy is paramount for strong electrical connections.

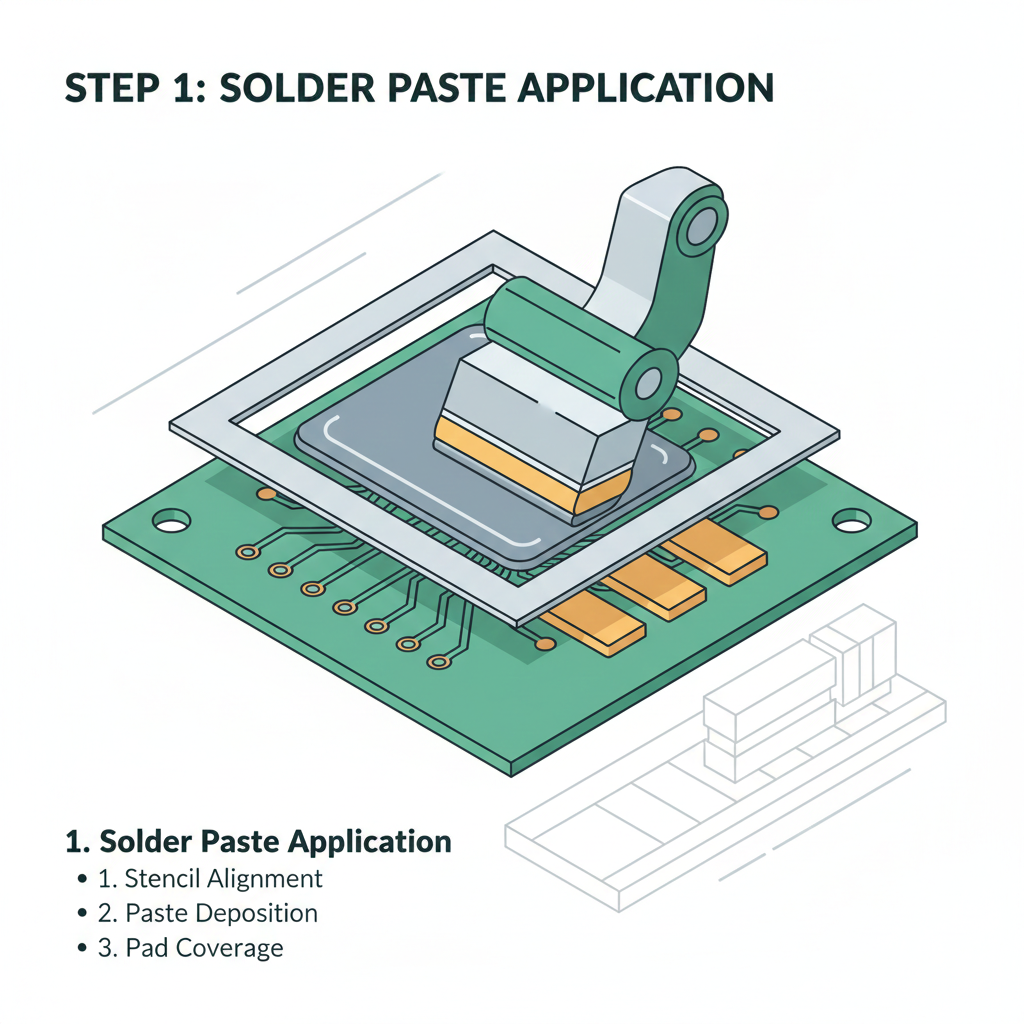

Step 2: Component Placement

Following the application of solder paste, our advanced pick-and-place machines take over. These automated systems rapidly and accurately place the surface-mount components onto the solder-pasted pads. This ensures components are perfectly aligned before the soldering process.

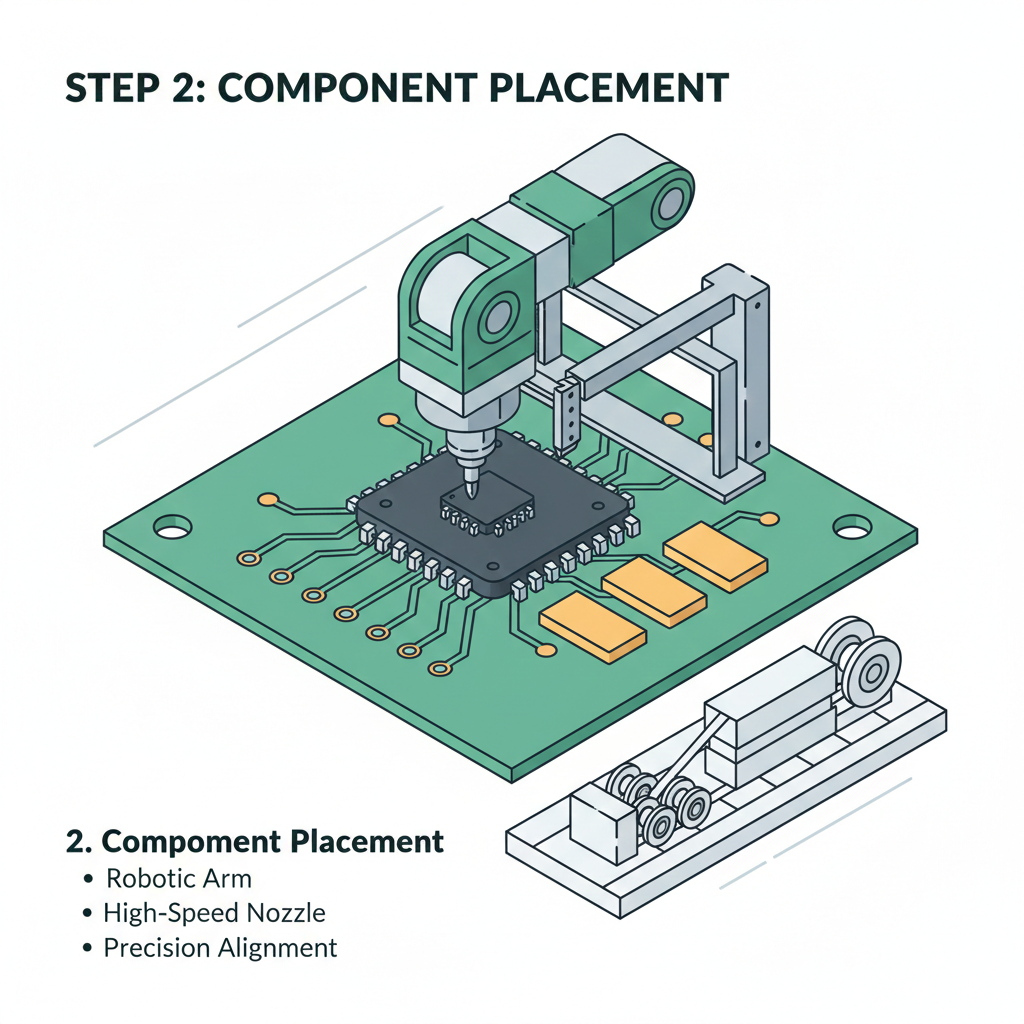

Step 3: Reflow Soldering

Once all components are precisely placed, the circuit boards proceed to the reflow oven. Here, controlled heating profiles gradually melt the solder paste, allowing it to flow and form robust, permanent electrical and mechanical connections between the components and the PCB pads. This stage is crucial for the integrity of every joint.

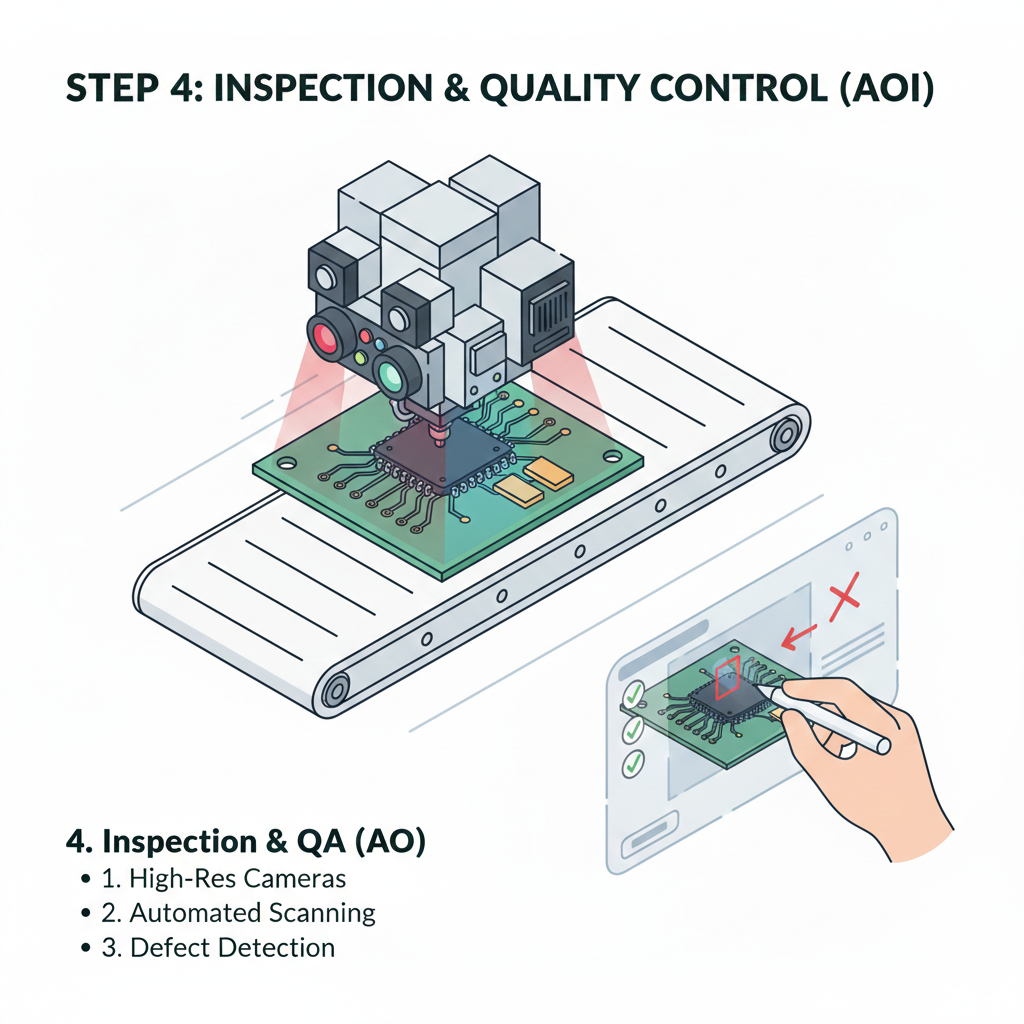

Step 4: Inspection & Quality Control (AOI)

The final key step in the automated PCB manufacturing process is rigorous inspection. We utilise Automated Optical Inspection (AOI) systems that use high-resolution cameras to scan the boards. This system meticulously checks for any soldering defects, missing components, or incorrect placements, ensuring every board meets our stringent quality standards before it moves to final testing.

How the SMT Process Consists of Steps for Success

Surface Mount Technology is the heart of modern electronics. You may wonder, the smt process consists of how many steps to achieve a perfect finish? While complexity can vary, the smt process consists of steps that focus on precision and thermal management.

The smt process steps involve placing components directly onto the surface of the printed circuit board. This allows for smaller designs and higher component density. Our technicians monitor the thermal profile of the reflow oven constantly. This ensures that delicate components are never damaged by excessive heat. By perfecting the assembly flow, we maintain high throughput without compromising on the integrity of the solder joints.

The Advantages of an Industrial PCB Manufacturing Process

Choosing a partner for your PCB manufacturing process is a critical business decision. An industrial PCB manufacturing process provides the repeatability needed for commercial success. We utilise advanced robotics to maintain a steady assembly line flow throughout the day. This automation reduces human error and increases the longevity of the final product.

We are more than just a provider. We are a dedicated PCB-manufacturing company that values your intellectual property. Our team works closely with yours to optimise designs for manufacturability. This collaborative approach often leads to lower costs and faster lead times. We believe that clear communication is just as important as technical skill.

Why Partner with a Specialist PCB Assembly Company?

First Choice Assembly stands out as a premier PCB assembly company in the region. We treat every project with the same level of care and professional rigour. Our clients trust us because we deliver on our promises. We understand that your reputation depends on the quality of the electronics we build.

Our engineers stay at the forefront of the industry. We constantly update our PCB assembly process to incorporate new techniques and materials. This dedication to continuous improvement ensures that your products remain competitive in a fast-moving market. From the initial PCB manufacturing process flow to the final functional test, we are your reliable partner.

Start Your Project Today

Are you looking for a partner to handle your PCB manufacturing requirements? Our team is ready to provide the expertise you need. We offer competitive pricing and unmatched lead times for all our clients.