Component Sourcing & Supply Chain

A reliable supply chain is essential for consistent PCB assembly. This page explains how First Choice Assembly sources high-quality components, manages lead times, and handles difficult-to-find parts, ensuring production runs smoothly and on schedule.

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

1. Does First Choice Assembly source components for me?

Yes, First Choice Assembly can source all required components for your PCB assembly project. This service simplifies procurement and ensures that the right parts are available for production.

Working with trusted UK and global suppliers, we manage the entire component supply chain to reduce delays and guarantee quality. Our sourcing services support both prototypes and full production runs.

2. How do you ensure components meet quality standards?

Components are sourced from approved suppliers and undergo inspection to verify compliance with specifications and industry standards. This helps maintain reliability and reduces the risk of faulty boards.

Testing includes visual checks, measurement of key parameters, and verification against manufacturer datasheets. These processes ensure every component meets strict quality requirements.

3. Can you source hard-to-find components in the UK?

Yes, First Choice Assembly specialises in sourcing rare or obsolete components for UK customers. Our established supplier network and industry expertise enable us to locate parts that may be difficult to find.

This ensures that even specialised or legacy designs can be produced without compromising timelines or functionality. We maintain flexibility to meet unique project requirements.

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

4. What is a Bill of Materials (BOM) and why is it important?

A Bill of Materials (BOM) is a detailed list of all components, parts, and materials required to assemble a PCB. It provides a blueprint for procurement, assembly, and cost estimation.

A clear and accurate BOM is essential for avoiding mistakes, ensuring consistency, and maintaining production schedules. It also helps manage inventory and component sourcing efficiently.

5. How are component shortages handled?

Component shortages are managed through proactive planning, supplier relationships, and alternative sourcing strategies. Critical parts can be pre-ordered or substituted with equivalent components when necessary.

First Choice Assembly works closely with clients to communicate potential delays and implement solutions that minimise disruption to production schedules. This ensures continuity even during supply chain challenges.

6. What lead times are typical for sourcing components?

Lead times vary depending on component availability, supplier location, and order size. Standard UK components are usually sourced within days, while rare or specialised parts may take several weeks.

Efficient planning and early procurement reduce delays and keep assembly timelines on track. Our team provides clear estimates to help clients schedule production accurately.

7. How is component authenticity verified?

Component authenticity is verified through supplier certification, batch traceability, and inspection upon receipt. This ensures that only genuine, high-quality parts are used in PCB assembly.

Verification prevents counterfeit or substandard components from compromising reliability and safety. It is a critical part of First Choice Assembly’s quality assurance process.

8. Can I supply my own components for assembly?

Yes, clients can provide their own components for assembly if preferred. This option allows flexibility for proprietary or pre-approved parts while still benefiting from professional assembly services.

All supplied components are inspected before assembly to ensure they meet quality and specification standards. This ensures reliability and performance are maintained.

9. How are obsolete components managed?

Obsolete components are handled by identifying suitable replacements or sourcing stock from trusted suppliers. First Choice Assembly advises clients on the best alternatives to maintain board functionality.

This approach ensures legacy designs can continue production without compromising quality or performance. Careful planning prevents delays due to unavailable parts.

10. What is just-in-time (JIT) component supply?

Just-in-time (JIT) component supply is a strategy where parts are delivered exactly when needed for production, reducing storage costs and inventory risk. It allows more efficient use of resources and minimises capital tied up in stock.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

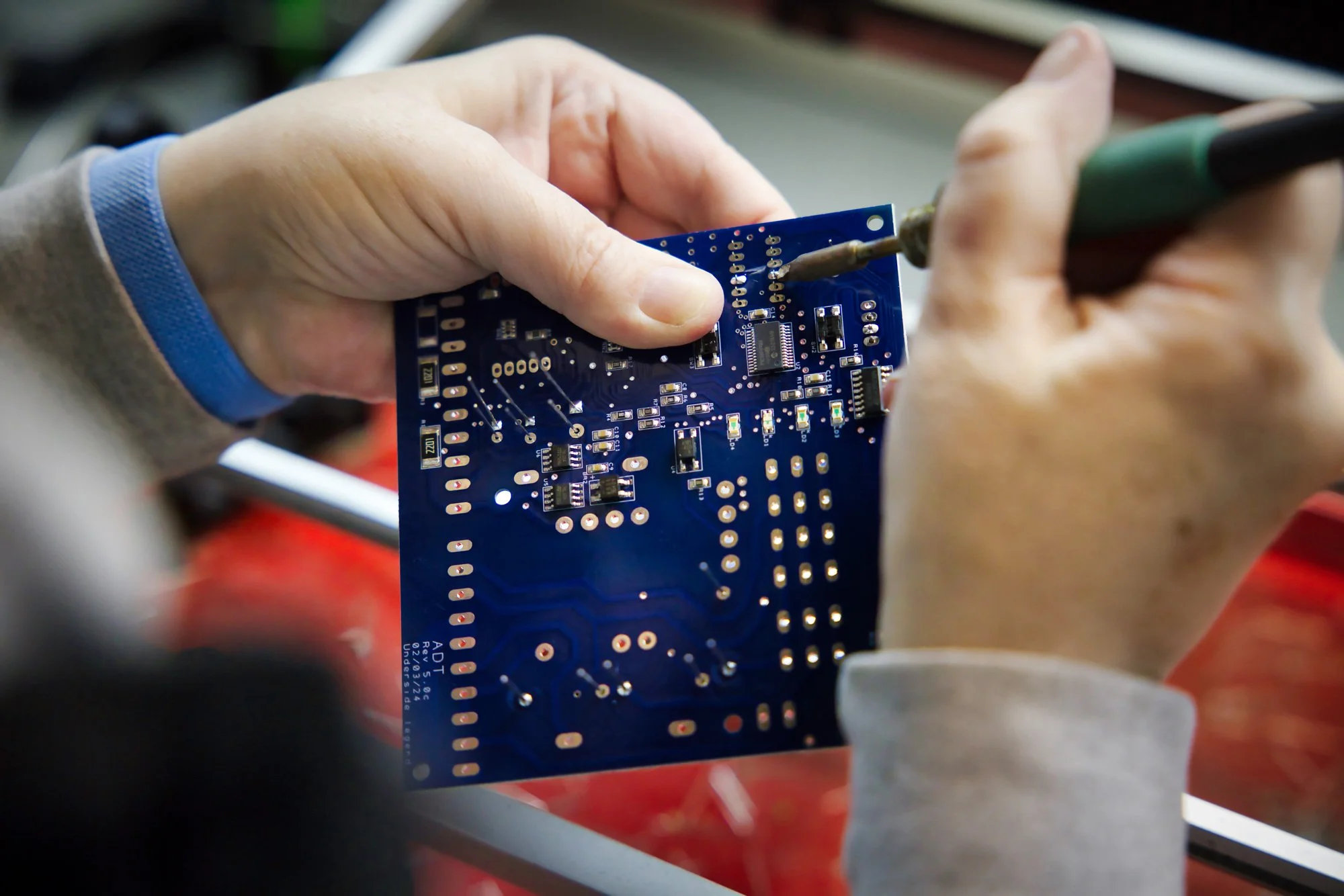

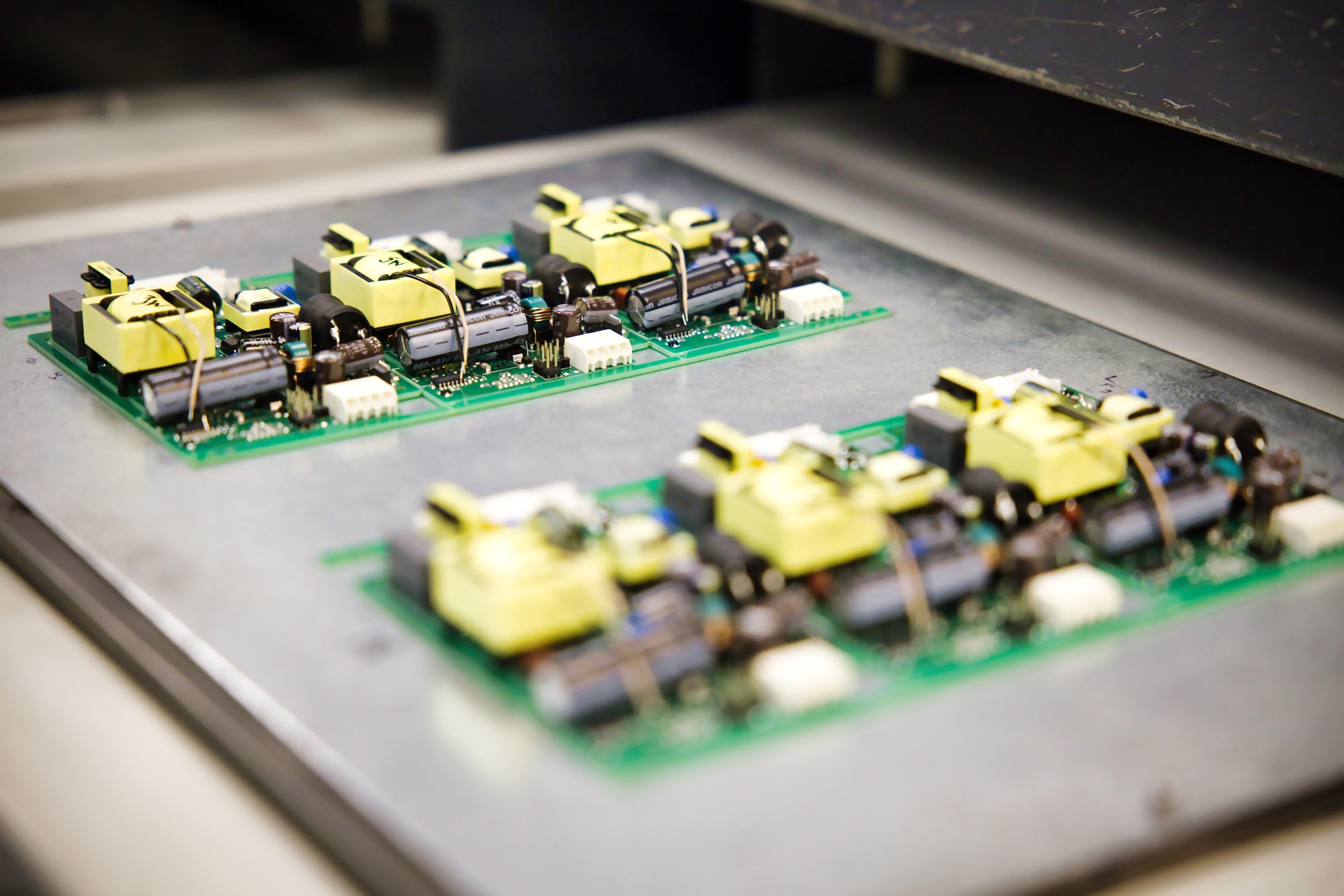

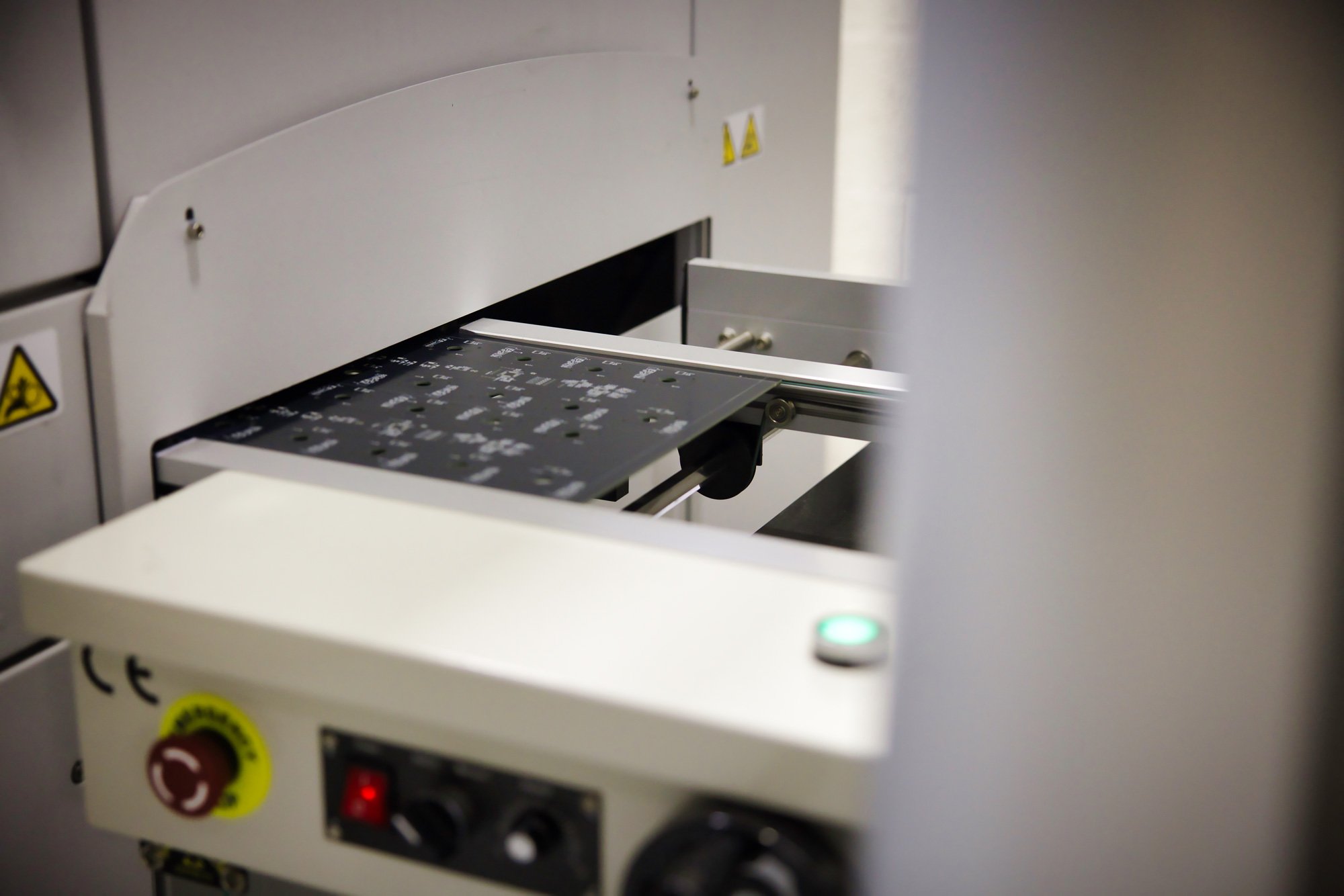

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors