Rework & Repair Services

Even with careful assembly, issues can arise during production or testing. This page introduces rework and repair services, detailing how faulty or damaged boards are identified, repaired, and tested to maintain product reliability and performance.

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

1. What is PCB rework and repair?

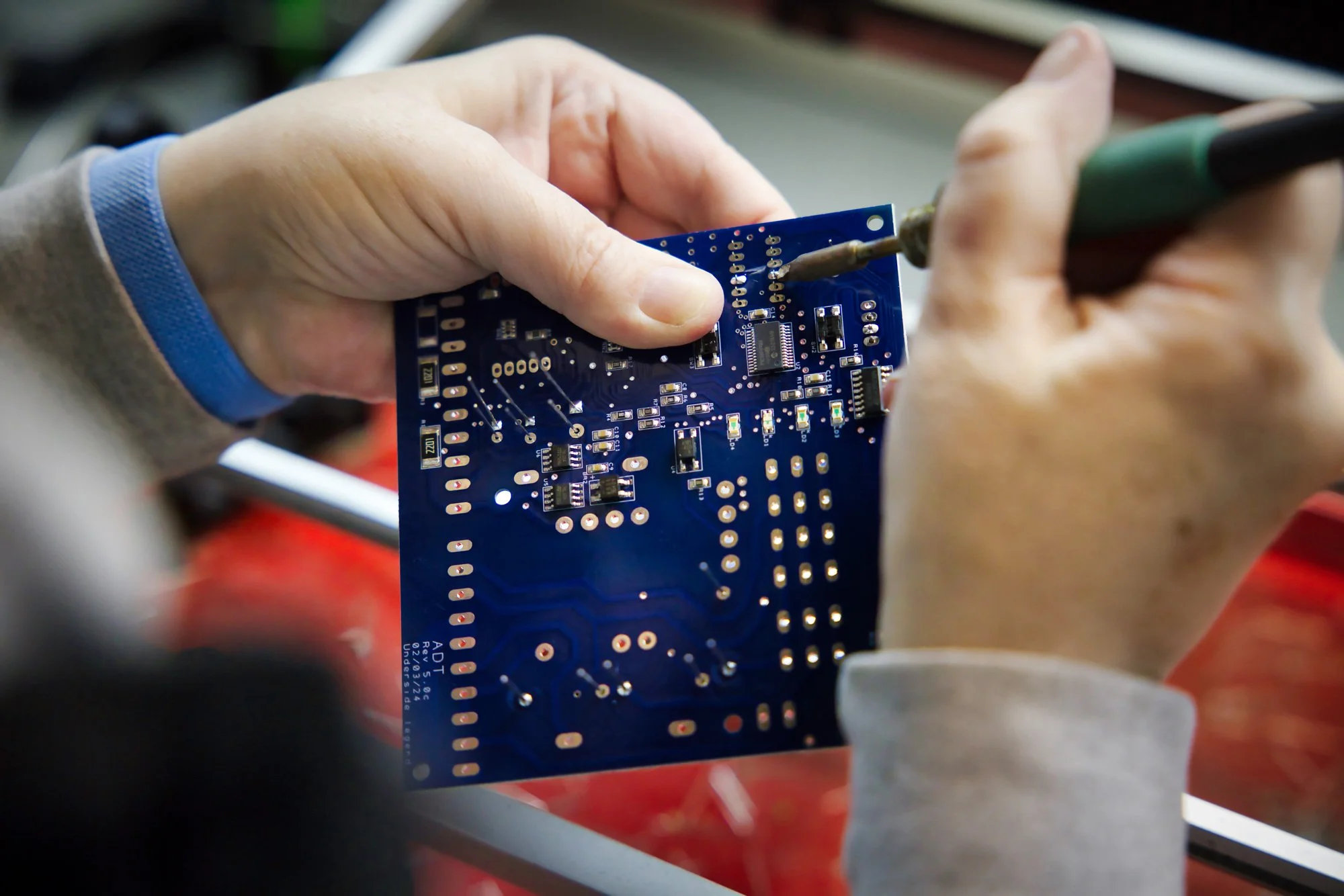

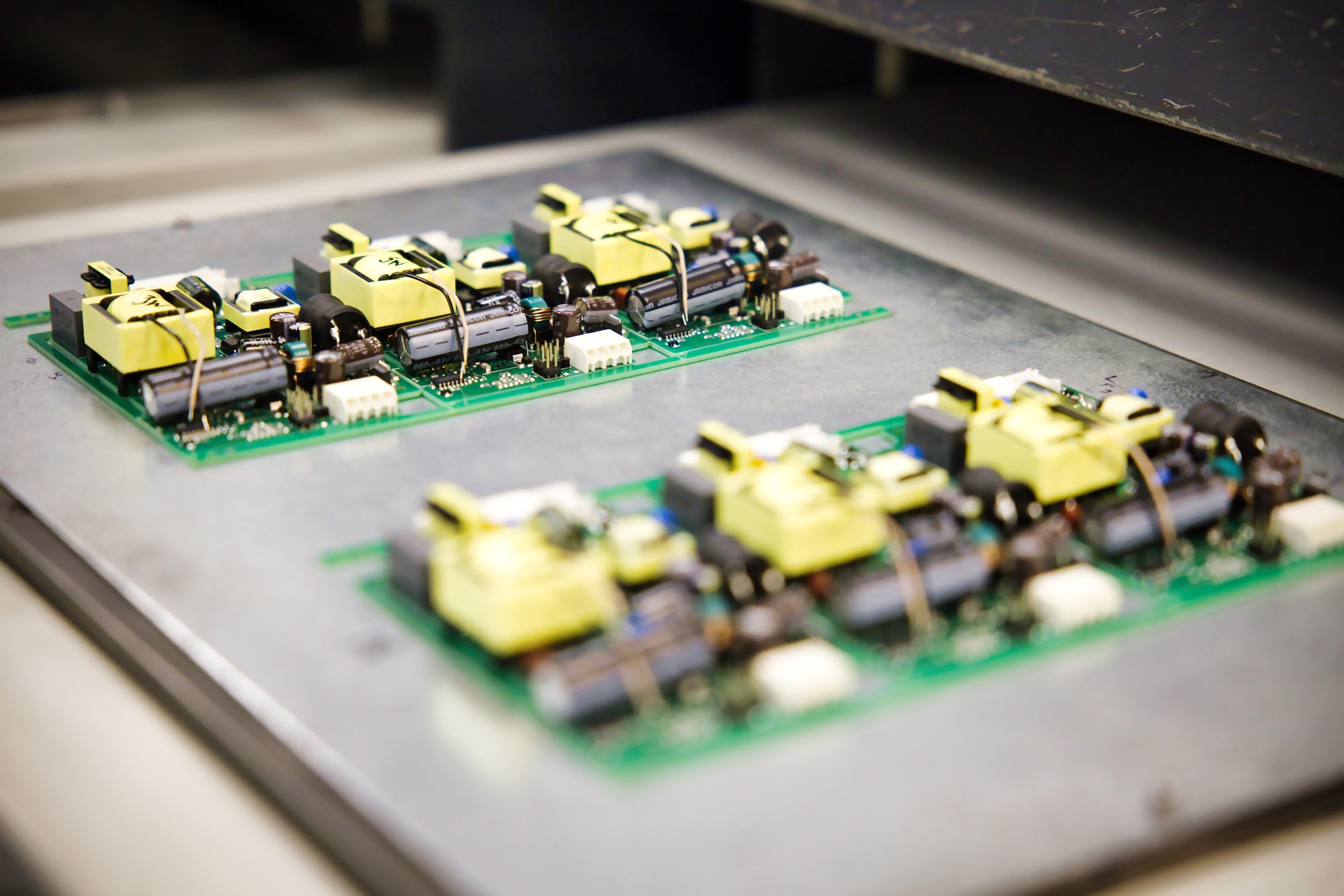

PCB rework and repair involve correcting faults or defects on an assembled board to restore full functionality. This can include soldering corrections, component replacement, or fixing damaged traces.

Rework is essential for prototypes, low-volume production, and boards that experience minor faults during testing or use. It ensures that defective boards do not go to waste and maintains product quality.

2. How are faulty boards identified?

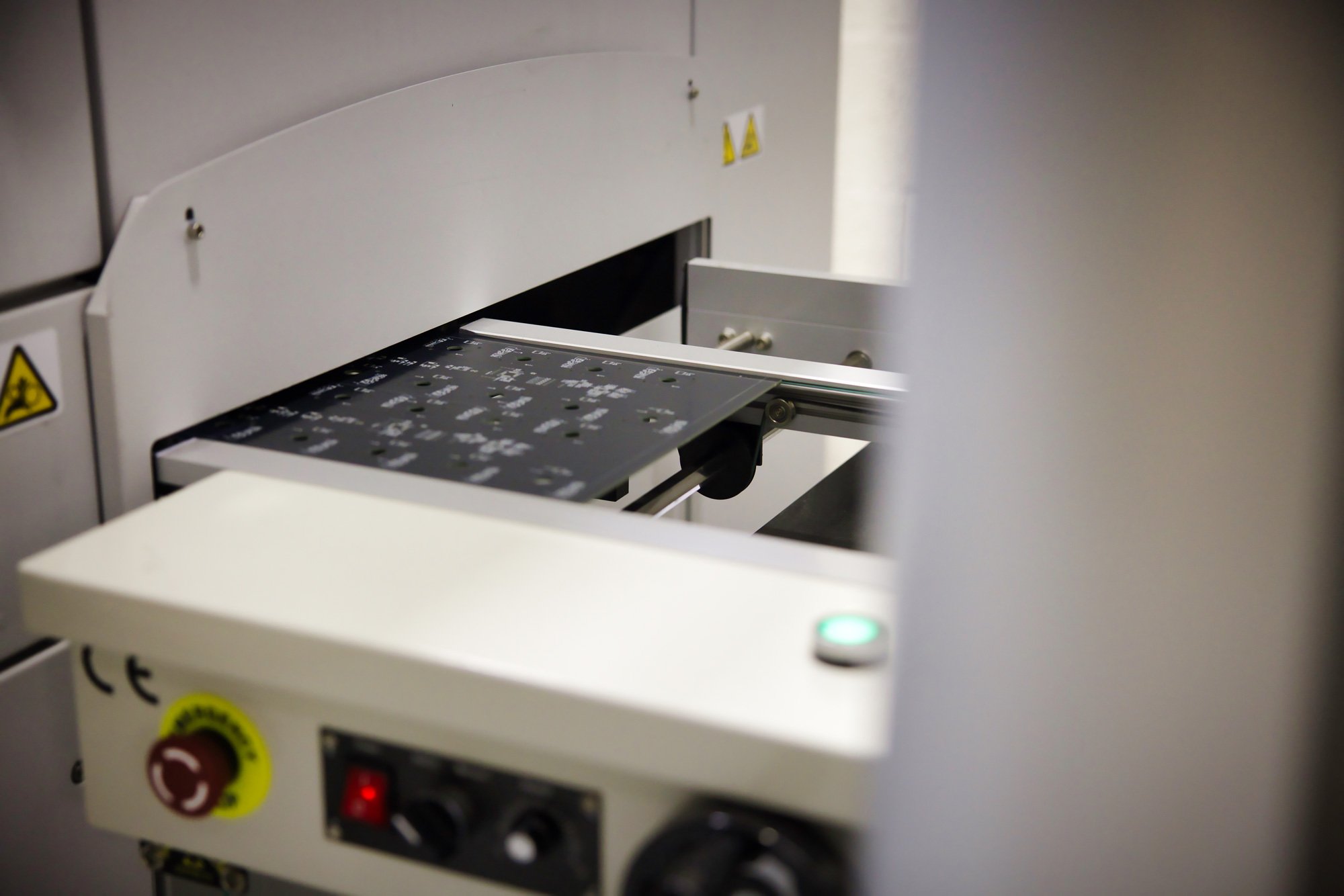

Faulty boards are identified through visual inspection, automated testing, and functional checks. This helps detect issues such as misaligned components, soldering defects, or electrical faults.

Early identification allows rework to be performed efficiently before boards enter full production or reach customers. Regular monitoring ensures ongoing quality control.

3. Can SMT components be repaired?

Yes, SMT components can be repaired or replaced when necessary using specialised tools and precise techniques. Careful rework ensures minimal disruption to surrounding components.

Repaired SMT boards are tested to verify full functionality and reliability. Skilled technicians ensure the repair meets the same standards as the original assembly.

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

4. What is the cost of PCB rework in the UK?

The cost of PCB rework varies depending on the complexity of the board, the number of components needing attention, and the type of defect. Small repairs may be relatively inexpensive, while complex boards require more labour and time.

UK providers offer transparent pricing based on the work required and the quality standards expected. Early identification of faults helps control overall costs.

5. How long does PCB repair take?

PCB repair timelines depend on the complexity of the fault and the availability of replacement components. Simple rework can be completed within hours, while more extensive repairs may take several days.

Efficient processes and experienced technicians minimise delays and ensure boards are returned in a timely manner. Communication with clients helps manage expectations.

6. Are repaired boards as reliable as new ones?

When repaired correctly, boards can be just as reliable as newly assembled ones. Professional rework ensures proper soldering, component placement, and testing to meet original specifications.

However, the reliability of repaired boards depends on the nature of the fault and the quality of the repair process. High standards and inspection are essential to maintain confidence.

7. What tools are used for PCB rework?

Tools for PCB rework include soldering irons, hot air rework stations, microscopes, tweezers, and specialised soldering equipment for SMT and through-hole components. These tools allow precise repair without damaging surrounding areas.

Automated and semi-automated systems may also be used for complex boards or high-density assemblies. Skilled technicians combine these tools with experience for effective repairs.

8. How is component replacement done safely?

Component replacement is done using controlled heating, careful desoldering, and precise placement to avoid damage to the PCB or nearby components. Flux, solder paste, and protective measures ensure a clean and reliable joint.

Boards are then inspected and tested to verify that the replacement functions correctly. This systematic approach maintains board integrity and reliability.

9. Can First Choice Assembly fix through-hole and SMT boards?

Yes, First Choice Assembly can repair both through-hole and SMT boards. Our technicians are experienced with a wide range of components and assembly types.

Repairs are performed following strict quality standards and verified through testing to ensure functionality and reliability. Both small and complex boards can be restored successfully.

10. What warranty is provided on reworked boards?

Reworked boards are typically covered by a warranty that guarantees the repair work and component replacement. This gives clients confidence that the boards will perform as intended.

The exact terms of the warranty depend on the scope of the rework and the components involved. First Choice Assembly ensures clear communication and support for all repaired boards.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors