PCB Prototyping

Prototyping allows engineers to test designs before committing to full production. This section covers rapid prototyping services, how prototypes are tested, and why early-stage evaluation saves time and costs in the long run.

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

1. What is PCB prototyping?

PCB prototyping is the process of creating a preliminary version of a printed circuit board to test its design, functionality, and manufacturability. It allows engineers to identify potential issues before committing to full-scale production.

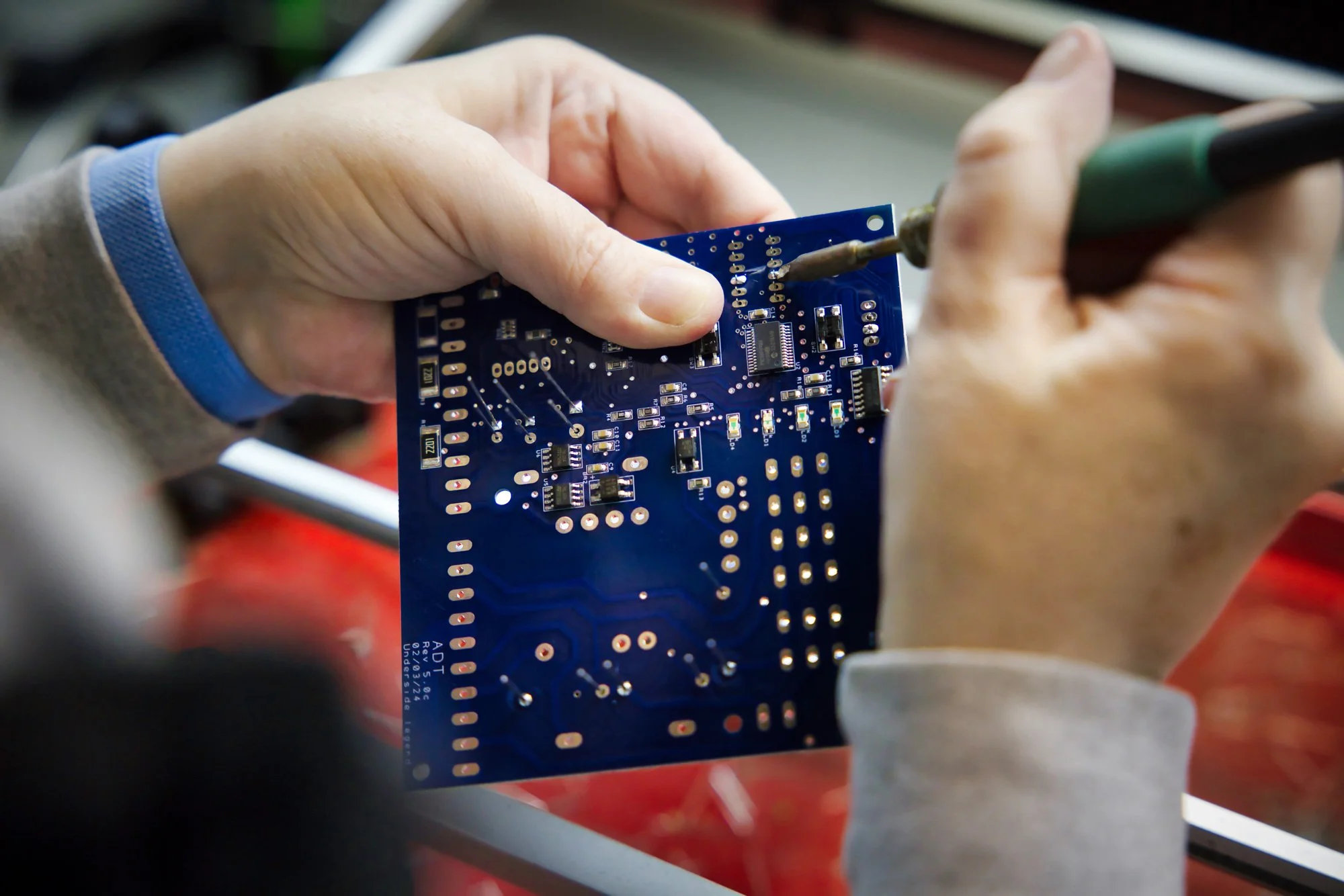

Prototypes can be produced in small quantities using both SMT and through-hole assembly techniques. They provide a practical, hands-on evaluation of the board’s design and performance.

2. Why is prototyping important for PCB design?

Prototyping helps catch design errors, component mismatches, or layout problems early in the development process. This prevents costly mistakes in larger production runs.

It also allows engineers to test the board in real-world conditions, ensuring functionality, reliability, and compliance with standards. Prototyping reduces risk and accelerates time-to-market.

3. How quickly can PCB prototypes be produced in the UK?

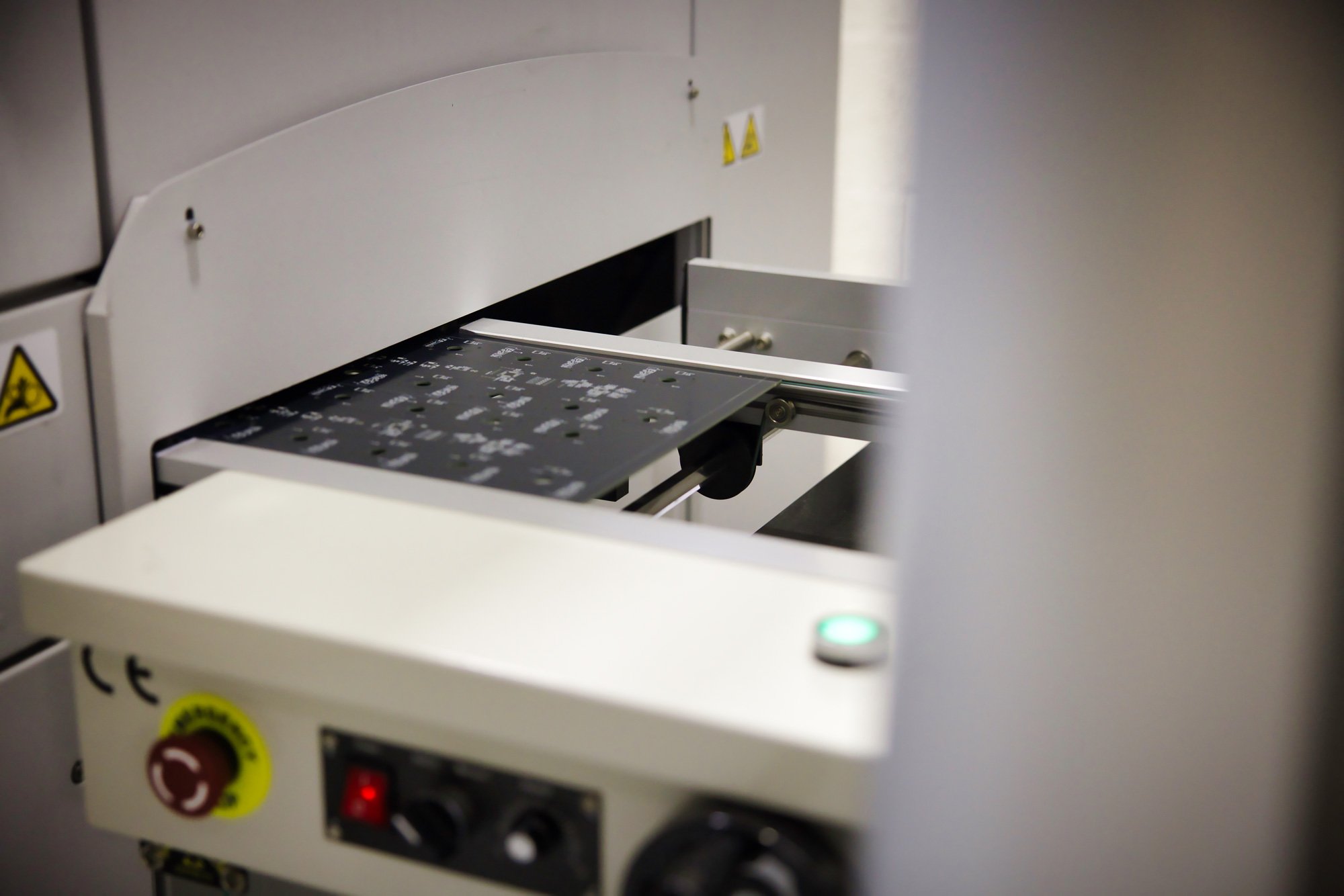

UK PCB prototypes can often be produced within a few days to a week, depending on complexity and component availability. Rapid-turn services cater specifically to designers needing fast feedback.

Lead times may vary for specialised components, but efficient UK suppliers minimise delays and ensure quick delivery of prototype boards. This speed supports agile development and design iteration.

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

4. What is the difference between prototype and production PCB assembly?

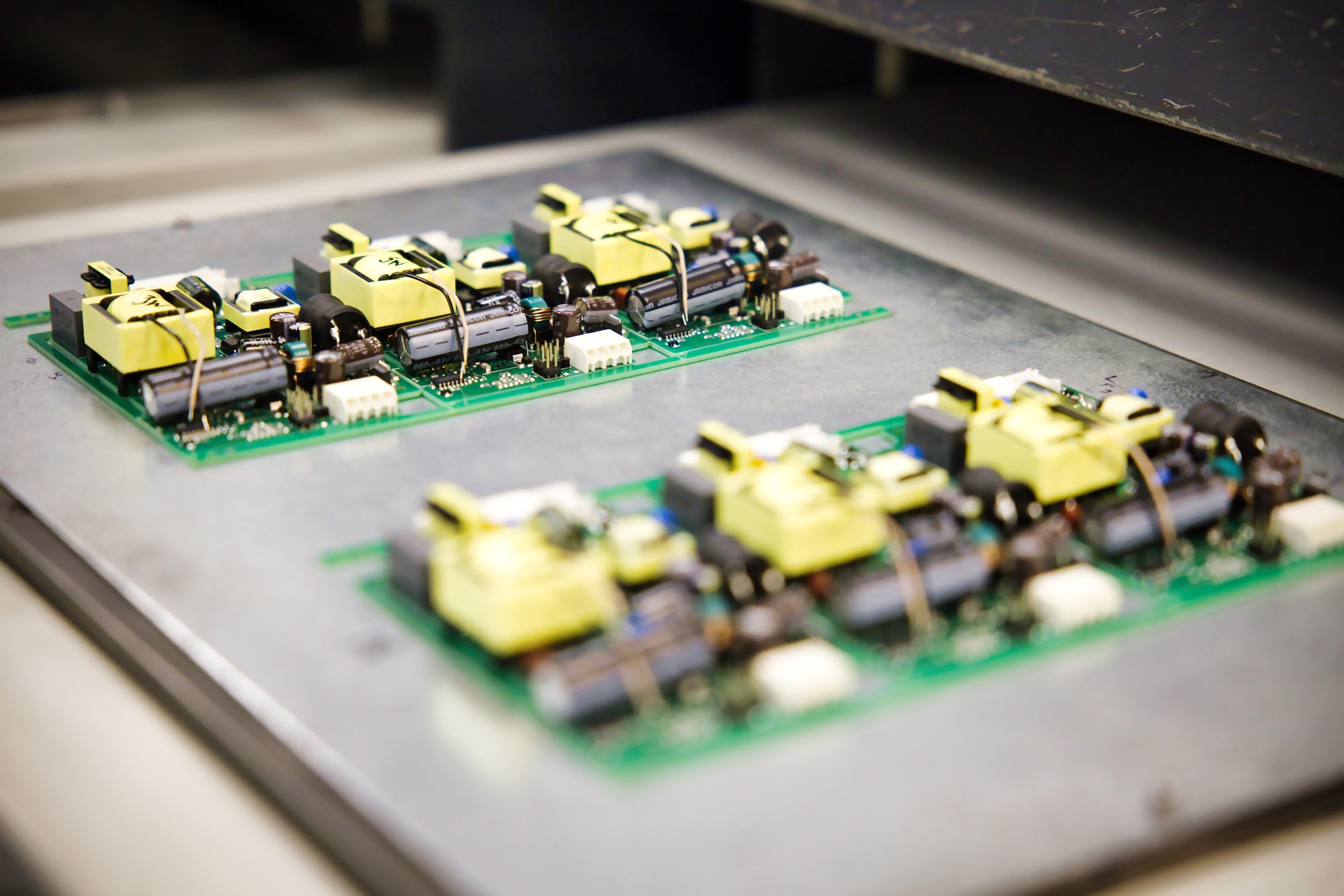

Prototype PCB Assembly focuses on small quantities for testing and design validation, prioritising flexibility and speed. Production assembly involves large-scale runs using automated lines for consistency and efficiency.

While prototypes are often hand-assembled or use semi-automated processes, production boards are manufactured to strict tolerances and quality standards to support high-volume delivery.

5. How are PCB prototypes tested?

PCB prototypes are tested using functional testing, visual inspection, and sometimes electrical testing to verify design integrity. Early testing identifies issues such as misaligned components or soldering defects.

This testing helps engineers refine layouts, correct errors, and ensure that the final design will perform reliably in production. It is a critical step in the development process.

6. Can small businesses afford PCB prototyping?

Yes, PCB prototyping is accessible to small businesses due to low-volume runs and flexible service options. Many UK providers offer cost-effective prototype services tailored to startups and SMEs.

The benefits of early testing and error detection often outweigh the modest cost of prototyping, making it a valuable investment for ensuring product success.

7. What common issues are found during prototyping?

Common issues include incorrect component placement, soldering defects, trace design errors, and unexpected electrical behaviour. These problems are easier to resolve in the prototype stage than in full production.

Prototyping allows engineers to identify and correct these errors, improving reliability and avoiding costly rework later. It is a proactive step to ensure design accuracy.

8. How does prototyping improve product quality?

Prototyping allows thorough testing and validation of the design before production. This ensures that the final product meets performance, reliability, and compliance standards.

By identifying and correcting errors early, prototyping reduces the risk of failure in the field and increases customer satisfaction. It helps create a robust, high-quality product.

9. What materials are used in PCB prototypes?

Prototypes typically use standard PCB substrates such as FR-4, but specialised materials like high-frequency laminates or flexible substrates may also be used. The choice depends on the intended application and device requirements.

Copper layers, solder masks, and silkscreens are applied in the same way as production boards to provide accurate testing and representation of the final product.

10. How many prototypes are recommended before production?

Typically, one to three prototype iterations are recommended before moving to full-scale production. The exact number depends on the complexity of the board and the level of design verification required. Multiple prototypes allow for thorough testing, refinement, and validation to ensure the final boards are reliable and manufacturable. It reduces risk and prevents costly errors in large production runs.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors