PCB Testing & Quality Control

Ensuring a PCB functions correctly requires rigorous testing and quality control throughout assembly. This page introduces the different testing methods used, including automated inspection and functional testing, and explains how quality standards are maintained at First Choice Assembly.

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

1. How is PCB assembly tested?

PCB assembly is tested using a combination of visual inspection, functional testing, and automated techniques to ensure all components are correctly placed and soldered. These tests verify both mechanical and electrical integrity.

Testing may also include in-circuit and end-of-line functional checks to identify faults before boards are delivered. Rigorous testing ensures high reliability and compliance with specifications.

2. What is functional testing of PCBs?

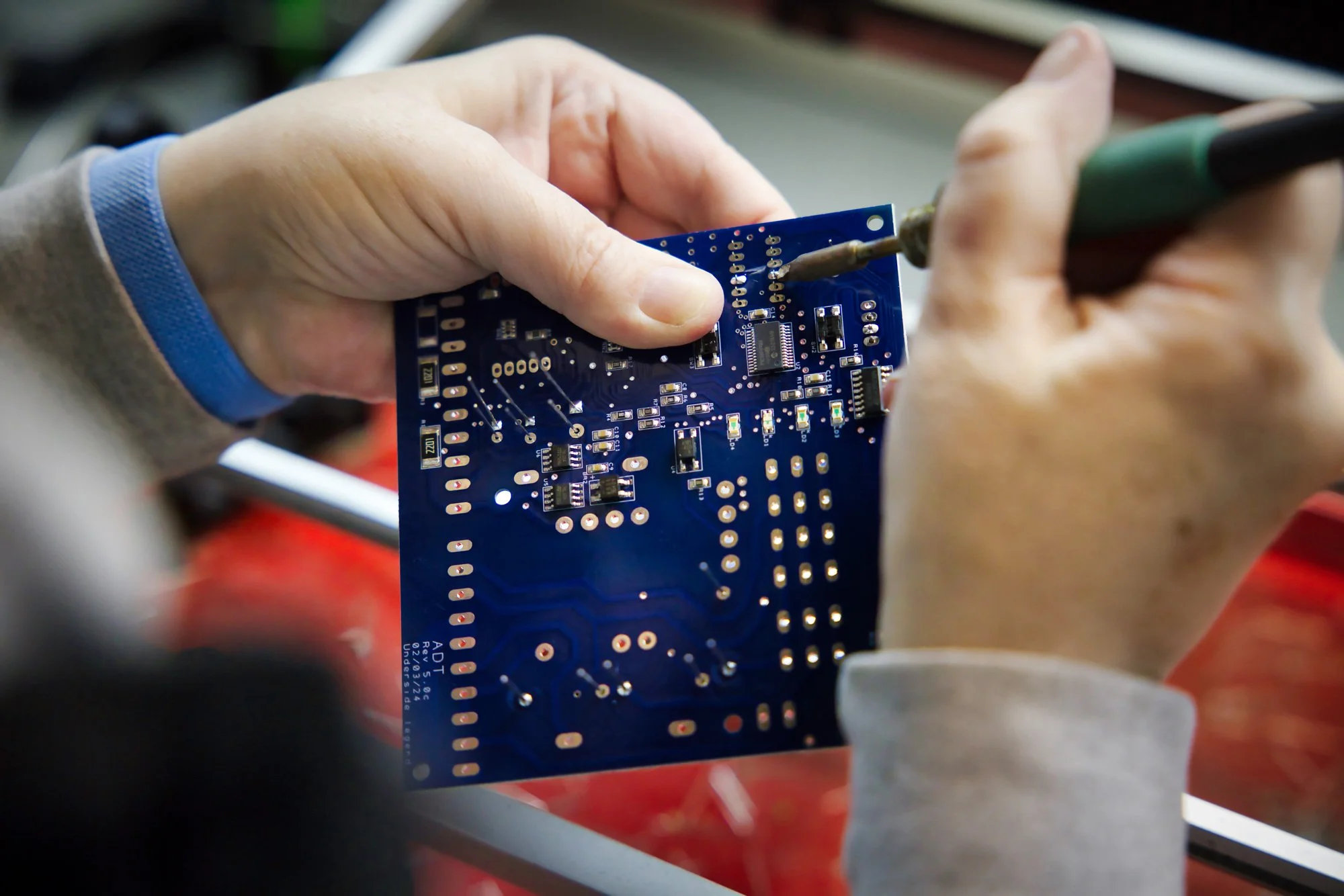

Functional testing involves powering the assembled PCB and verifying that it performs its intended functions correctly. This checks that components, circuits, and signals operate as designed.

It can include simulation of real-world conditions and measurement of electrical outputs to ensure the board meets performance requirements. Functional testing is essential for detecting operational faults early.

3. What are common PCB assembly defects?

Common defects include cold solder joints, solder bridges, missing or misaligned components, and damaged traces. These can result from poor soldering, incorrect placement, or handling errors.

Other issues such as short circuits or open circuits can also occur, potentially compromising the board’s functionality. Early detection and correction prevent costly failures in production or the field.

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

4. How does First Choice Assembly ensure quality?

First Choice Assembly ensures quality through stringent inspection procedures, ISO-compliant processes, and experienced staff overseeing every assembly stage. Each board undergoes visual, automated, and functional checks to meet high standards.

Our commitment to continuous improvement, adherence to UK standards, and rigorous supplier management maintains consistent reliability and customer confidence. Quality is built into every stage of the assembly process.

5. What is in-circuit testing (ICT)?

In-circuit testing (ICT) is a method of checking each component and circuit on a PCB for proper placement, orientation, and electrical connectivity. It identifies open circuits, shorts, and incorrect component values.

ICT is often used in production environments to catch assembly errors early and ensure each board meets strict specifications before functional testing. It is a key part of quality assurance for complex PCBs.

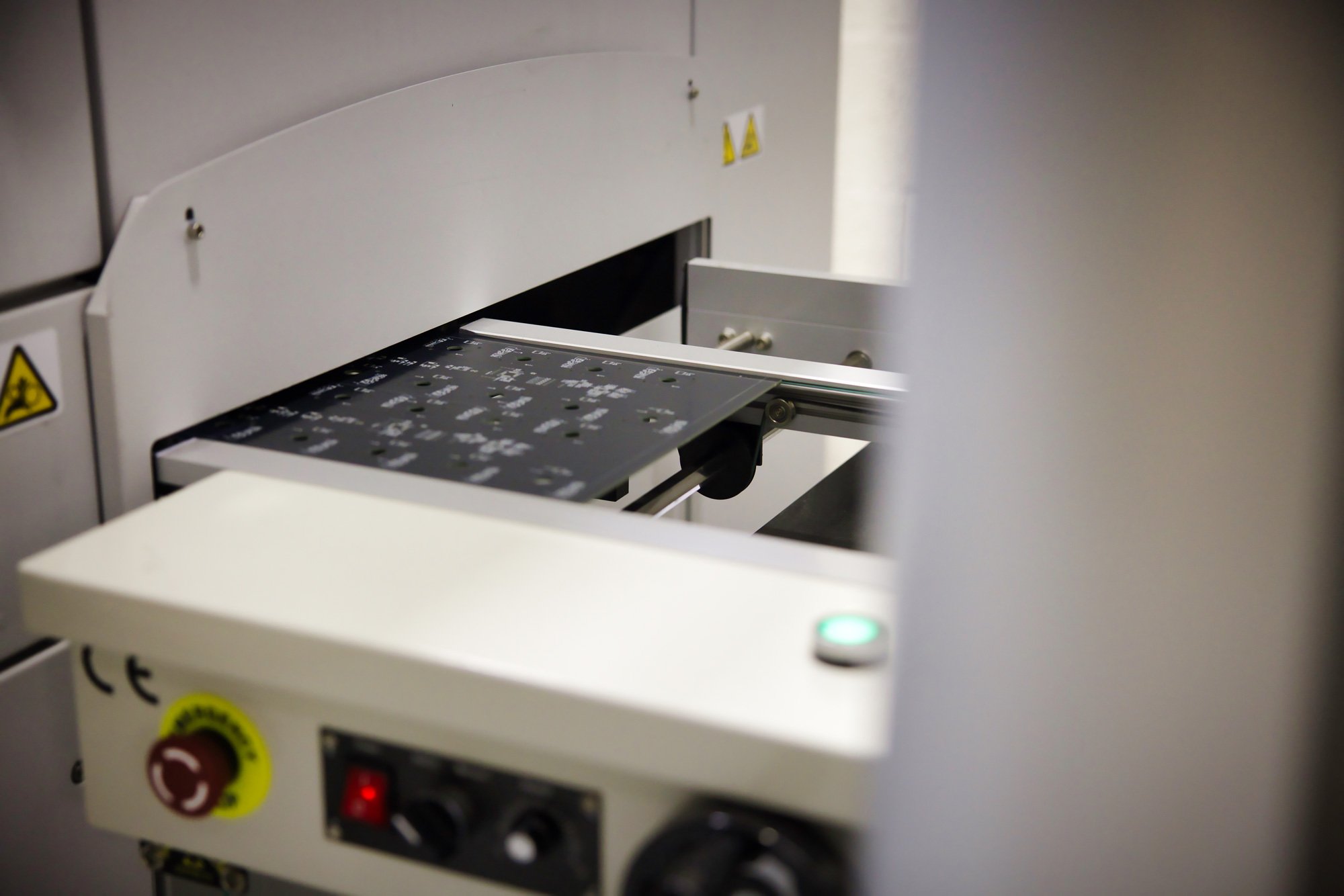

6. What is automated optical inspection (AOI)?

Automated optical inspection (AOI) uses cameras and software to scan PCBs for visual defects such as misaligned, missing, or incorrectly soldered components. It provides fast, accurate, and repeatable inspection across multiple boards.

AOI reduces the risk of human error and is particularly effective for high-density SMT boards where manual inspection would be challenging. It is an essential tool in modern PCB quality control.

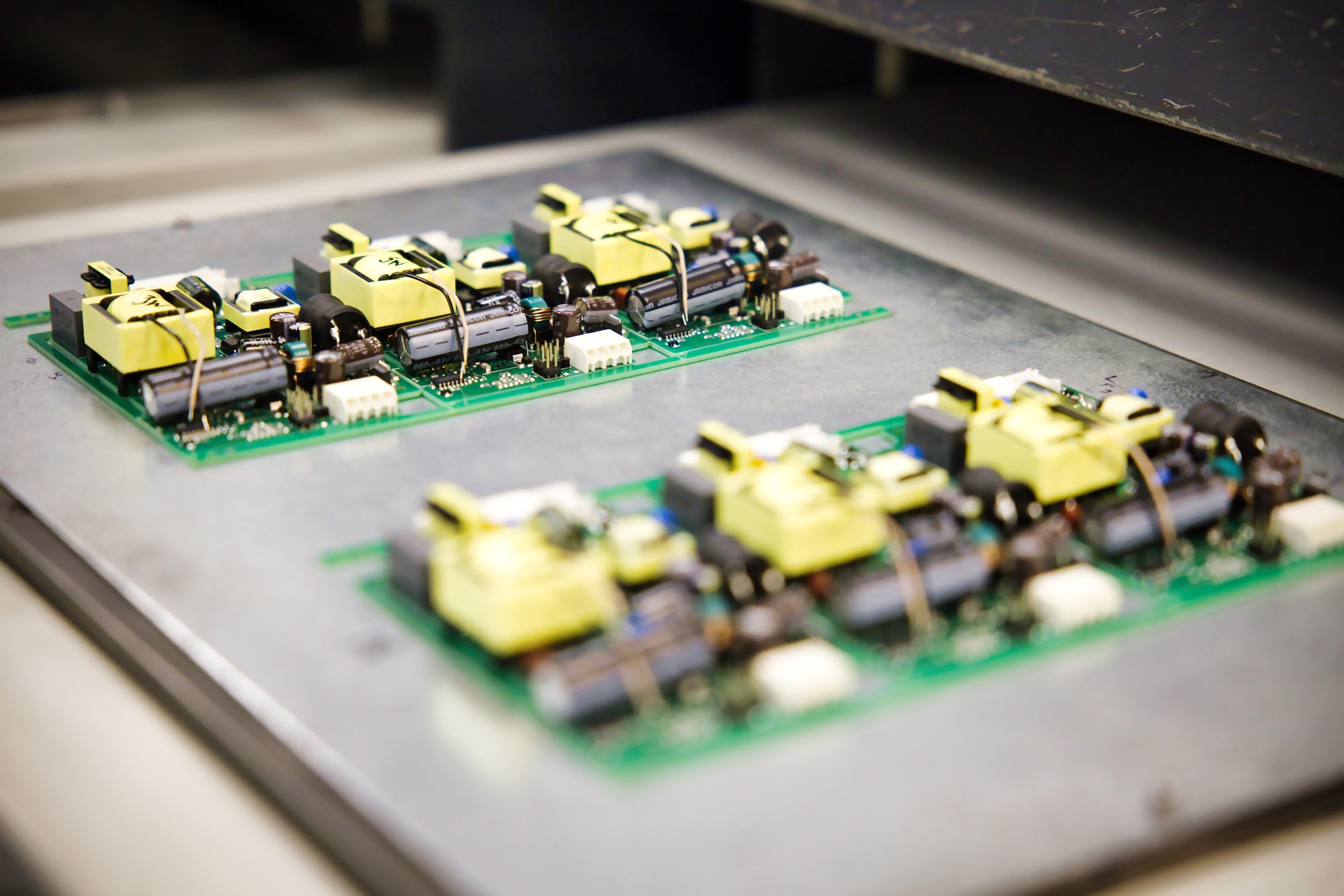

7. How are PCBs tested for electrical reliability?

Electrical reliability testing involves checking continuity, insulation resistance, and signal integrity under normal and stress conditions. It ensures the PCB functions correctly and safely over its expected lifespan.

Testing may also include thermal cycling or vibration testing for boards in industrial or automotive applications. These tests identify potential failure points before the board reaches the customer.

8. What UK standards apply to PCB assembly?

PCB assembly in the UK must comply with standards such as IPC-A-610 for acceptability, ISO 9001 for quality management, and RoHS for environmental compliance. These standards ensure consistency, safety, and regulatory adherence.

Compliance demonstrates a company’s commitment to quality and provides assurance to customers across industries. Following these standards is essential for high-reliability electronics.

9. How much does PCB testing cost?

PCB testing costs vary depending on the board complexity, test type, and production volume. Functional and in-circuit testing for small runs may be slightly higher per board, while larger production runs reduce the cost per unit.

Automated techniques like AOI help control costs by reducing labour and inspection time. Choosing a reliable UK provider ensures fair pricing while maintaining high-quality standards.

10.How often should PCBs be inspected during production?

PCBs should be inspected at multiple stages of assembly, including after solder paste application, component placement, and final assembly. Regular inspections help catch defects early and maintain consistent quality.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors