Small to Medium Volume PCB Production

Not every project requires high-volume manufacturing. Small to medium volume PCB production offers flexibility, cost efficiency, and faster turnaround for UK businesses. This page outlines the benefits of low-to-medium volume assembly and how it fits into prototype and production workflows.

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

1. What is considered small and medium-volume PCB assembly?

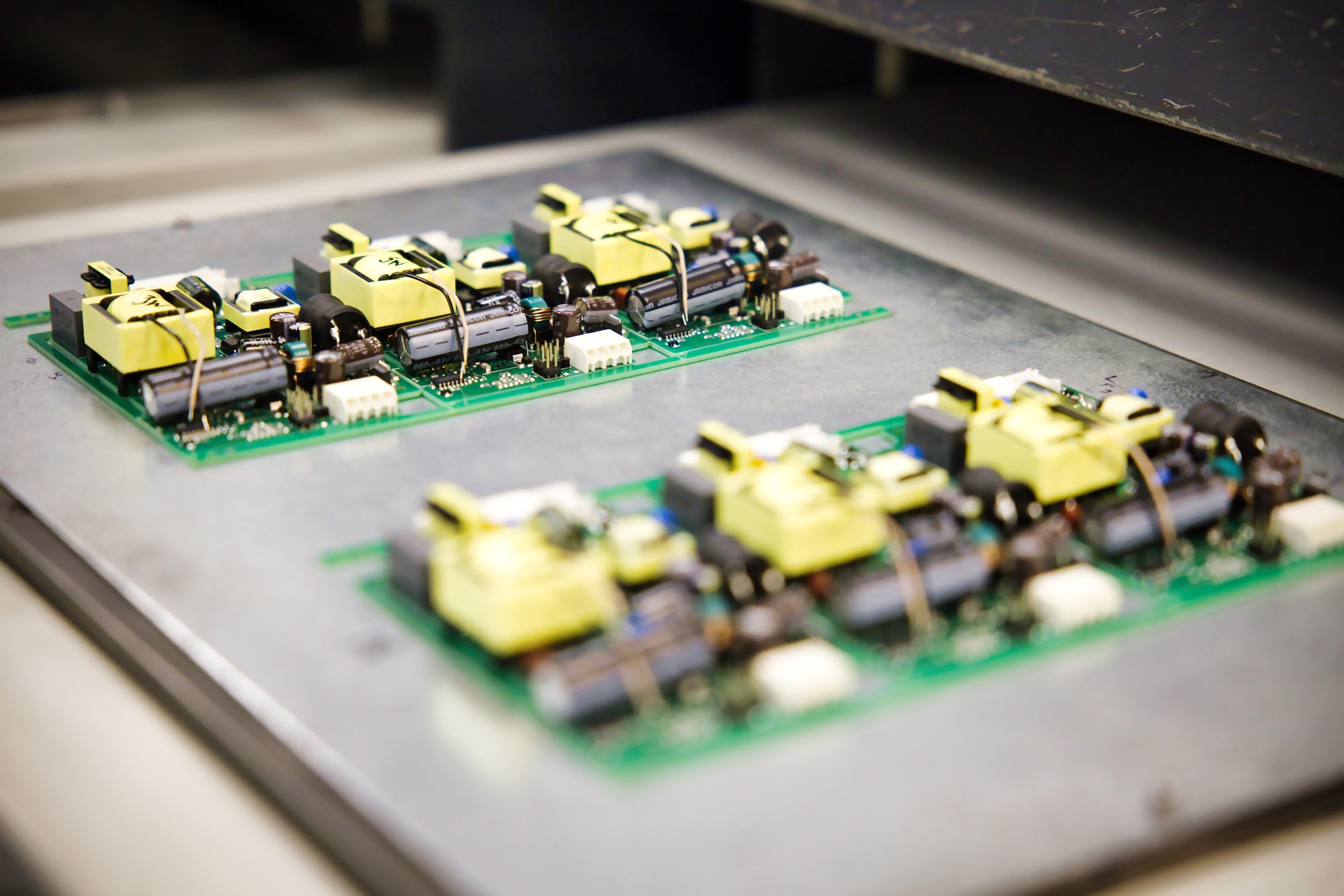

Small-volume PCB assembly typically involves tens to a few hundred boards, while medium-volume runs may range from several hundred to a few thousand. These volumes are ideal for prototypes, pilot production, and short-run manufacturing.

Such runs allow businesses to test designs or meet seasonal demand without committing to large-scale production. UK suppliers specialise in flexible production for these quantities.

2. Can I produce PCBs in low quantities cost-effectively?

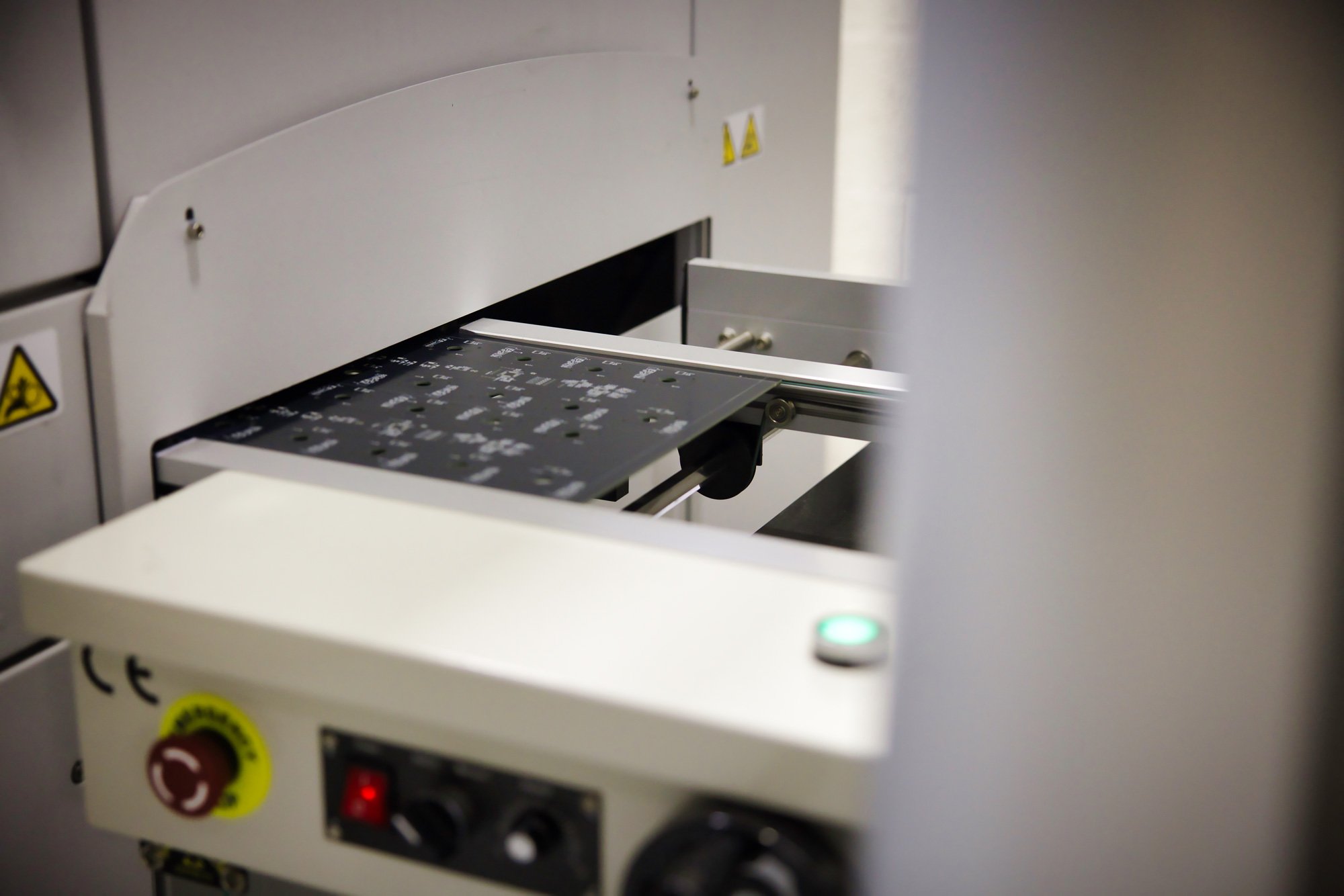

Yes, low-volume PCB production can be cost-effective, especially when using UK-based providers with efficient processes. Advances in automated assembly and flexible workflows make small runs financially viable.

This allows startups, SMEs, and research teams to test designs and bring products to market without high upfront costs. Small runs can also reduce risk by catching design issues early.

3. How quickly can medium-volume orders be fulfilled?

Medium-volume orders can often be completed within one to four weeks, depending on complexity and component availability. UK suppliers offer agile scheduling to meet business timelines.

Planning ahead and ensuring components are sourced in advance helps reduce delays. Reliable production partners can provide accurate estimates and meet delivery commitments.

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

4. What are the benefits of using a UK PCB assembly service for SMEs?

UK assembly services offer fast communication, shorter lead times, and local regulatory compliance. SMEs benefit from working closely with expert engineers who understand their requirements.

Local assembly also provides better control over quality, reduces shipping costs, and allows easier collaboration for prototypes or design changes. It strengthens reliability and customer confidence.

5. How is pricing calculated for medium-volume PCB assembly?

Pricing is based on factors such as board complexity, component count, production volume, and testing requirements. Higher volumes often reduce the cost per board due to economies of scale.

Additional services, such as supply chain management, inspection, or specialised components, may affect the total price. Clear quotes from UK suppliers ensure transparency and cost predictability.

6. Can production volumes be scaled later?

Yes, small and medium-volume runs can often be scaled to larger production quantities. Flexible UK assembly providers plan for growth, allowing businesses to ramp up production as demand increases.

Scaling ensures continuity without redesigning processes or compromising quality. This flexibility supports evolving product lines and business growth.

7. Are there minimum order quantities?

Minimum order quantities vary by supplier and board complexity, but many UK providers offer low or no minimums for prototypes and small runs. This makes it easier for SMEs to test products without large commitments.

Higher-volume production usually has minimums to ensure efficiency and cost-effectiveness. Transparent communication with the assembler helps set realistic expectations.

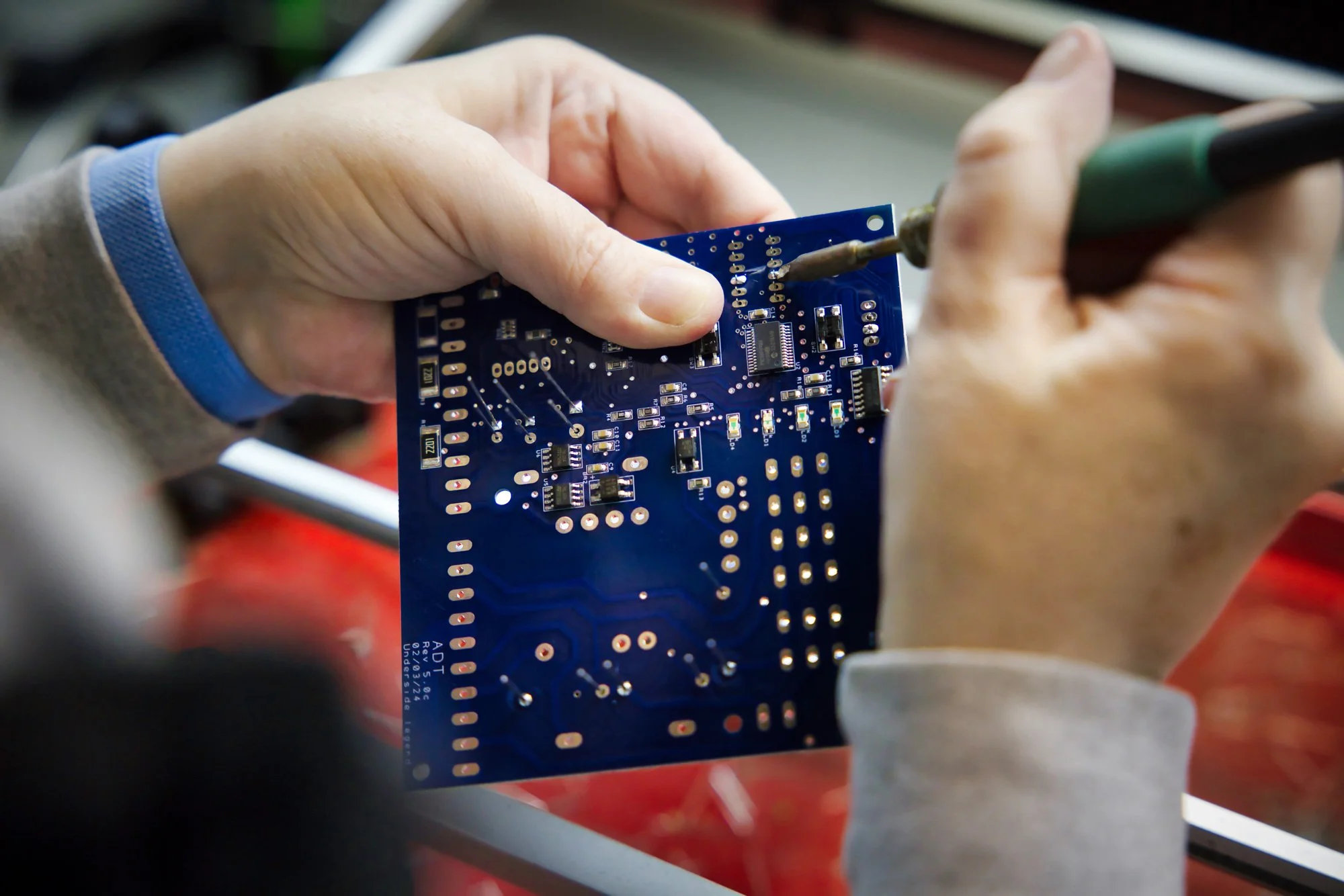

8. How is quality maintained across small batches?

Quality is maintained through rigorous inspection, testing, and process controls, even in small batches. Each board is checked for correct component placement, soldering, and functionality.

Using the same procedures as full-scale production ensures that every board meets industry standards. Consistency is key, regardless of batch size.

9. How flexible is UK PCB assembly for custom designs?

UK assembly providers offer flexibility to accommodate custom designs, unusual components, or mixed-technology boards. Engineers can adjust assembly processes to meet specific project requirements.

This allows businesses to innovate and produce specialised boards without compromising on quality or timelines. Custom solutions are achievable even for low to medium volumes.

10. What lead times can I expect for medium-volume production?

Lead times typically range from one to four weeks depending on complexity, component availability, and supplier capacity. Clear planning and communication help meet production schedules reliably.

UK-based providers can often expedite orders when necessary, providing flexibility for project deadlines or market demands. Efficient supply chain management supports predictable lead times.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors