Regulatory Compliance & Standards

Compliance with UK and international standards is crucial for safe, reliable, and market-ready PCBs. This page outlines key regulations, such as RoHS and IPC standards, and explains the quality management processes that ensure every board meets rigorous requirements.

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

1. What UK standards apply to PCB assembly?

PCB assembly in the UK is guided by standards such as IPC-A-610 for acceptability, ISO 9001 for quality management, and RoHS for environmental compliance. These standards ensure consistent, reliable, and safe electronic products.

Adhering to UK and international standards demonstrates professionalism and builds customer confidence. Compliance helps prevent defects and ensures products meet industry requirements.

2. What is RoHS compliance?

RoHS (Restriction of Hazardous Substances) compliance restricts the use of certain hazardous materials in electronics, such as lead, mercury, and cadmium. It ensures that PCBs are safer for users and the environment.

Manufacturers in the UK and EU must follow RoHS regulations to sell electronics legally. Compliance also demonstrates a company’s commitment to environmental responsibility.

3. How does IPC certification impact quality?

IPC certification sets recognised standards for PCB assembly, soldering, and inspection. Following IPC guidelines ensures boards meet high-quality and reliability requirements.

Certified processes reduce defects, improve consistency, and provide assurance to customers that the assembly meets global standards. It is a mark of technical expertise and professionalism.

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

4. Are all PCBs manufactured in the UK compliant?

Not all PCBs are automatically compliant; each board must meet relevant standards depending on its design, application, and customer requirements. Manufacturers must follow regulations such as RoHS and IPC-A-610 to ensure compliance.

Working with a certified UK provider ensures that all boards are assembled and tested according to industry standards. Compliance reduces the risk of legal or operational issues.

5. What environmental regulations affect PCB assembly?

Environmental regulations in the UK, such as RoHS and WEEE (Waste Electrical and Electronic Equipment), restrict hazardous substances and govern disposal. They require manufacturers to minimise environmental impact throughout production.

Compliance ensures that PCBs are safe for both users and the environment. It also demonstrates corporate responsibility and adherence to legal requirements.

6. How is quality management certified?

Quality management is typically certified through ISO 9001, which sets international standards for consistent processes and continuous improvement. It ensures that assembly practices maintain high reliability and meet customer expectations.

Certification requires regular audits and documentation of procedures, providing transparency and accountability. It reassures clients that quality is embedded in every stage of production.

7. Do UK companies require CE marking?

CE marking is required for electronics that fall under European directives and sold within the UK and EU. It demonstrates that the product complies with safety, health, and environmental regulations.

While not every PCB requires CE marking on its own, final products incorporating PCBs may need certification. Manufacturers ensure compliance to support legal sale and market access.

8. How is regulatory compliance verified?

Regulatory compliance is verified through documentation, testing, inspections, and audits. Providers maintain certificates and records to demonstrate adherence to UK and international standards.

Verification ensures that all components, assembly processes, and final boards meet legal and quality requirements. It also supports traceability in case of product issues.

9. Can non-compliant components be used?

Non-compliant components should not be used in PCBs intended for regulated markets. Using them can result in safety issues, legal penalties, and product recalls.

UK providers only use approved, certified components or provide alternatives that meet the required standards. Compliance is essential for reliability and customer confidence.

10. What warranty is provided on reworked boards?

Reworked boards are typically covered by a warranty that guarantees the repair work and component replacement. This gives clients confidence that the boards will perform as intended.

The exact terms of the warranty depend on the scope of the rework and the components involved. First Choice Assembly ensures clear communication and support for all repaired boards.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

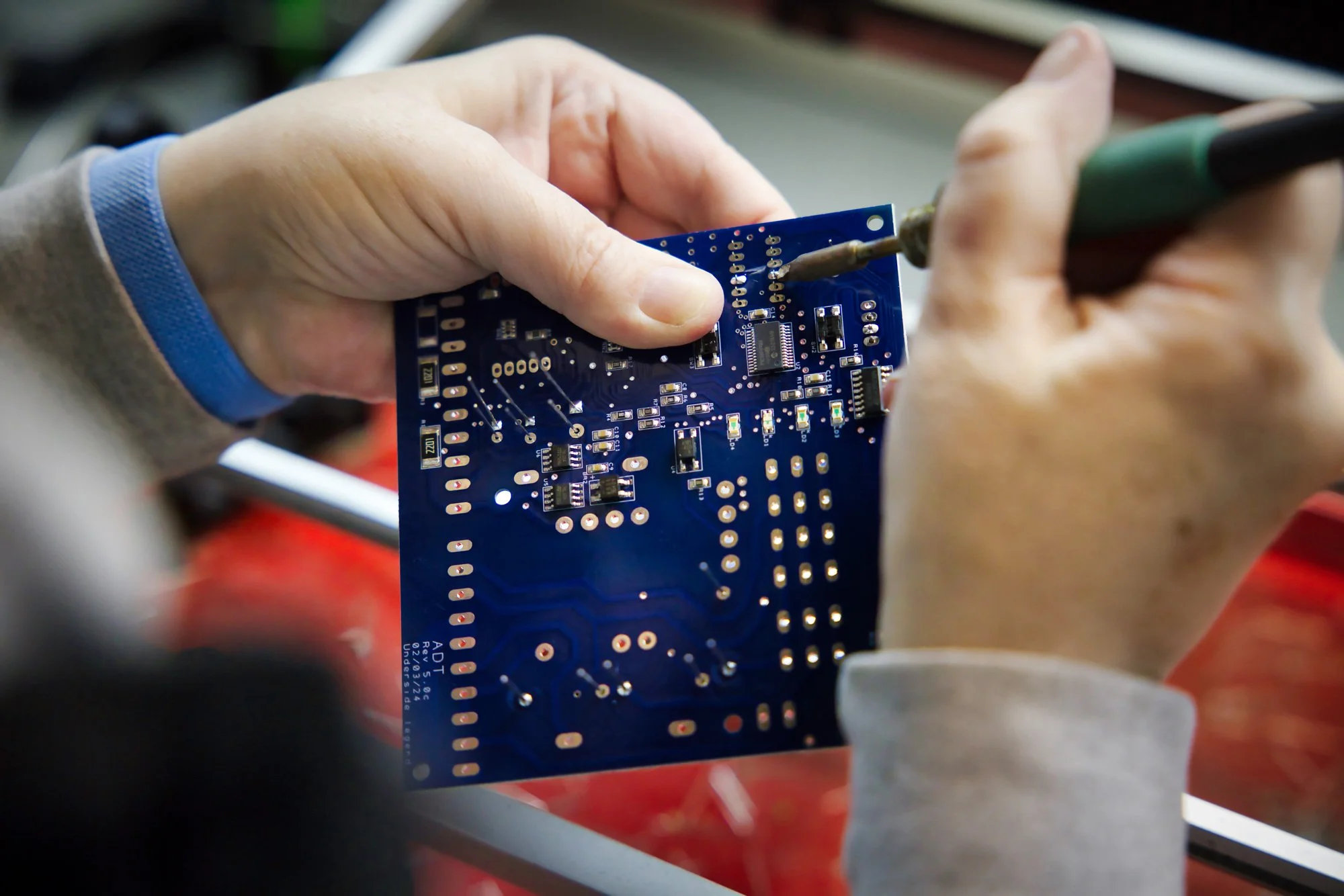

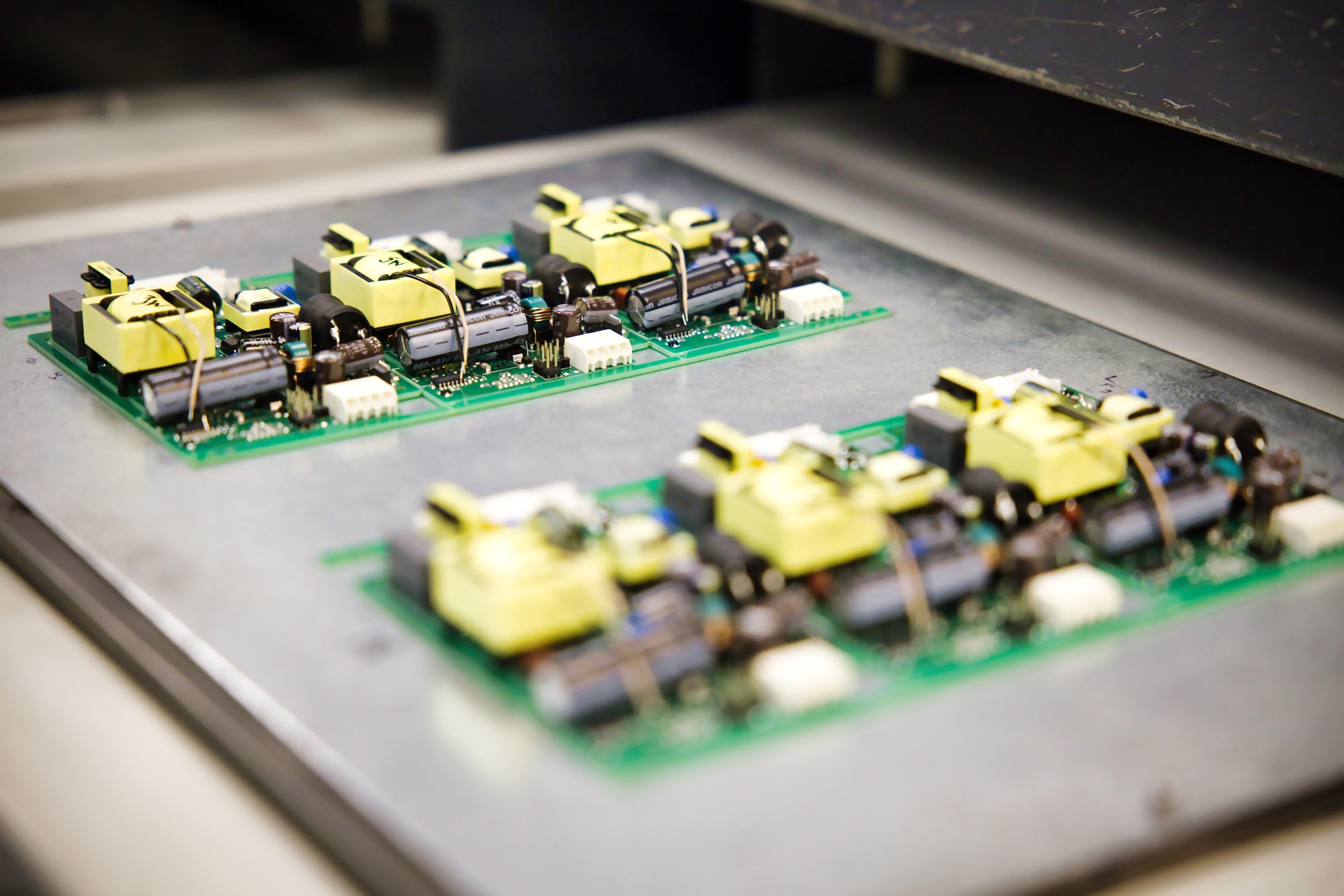

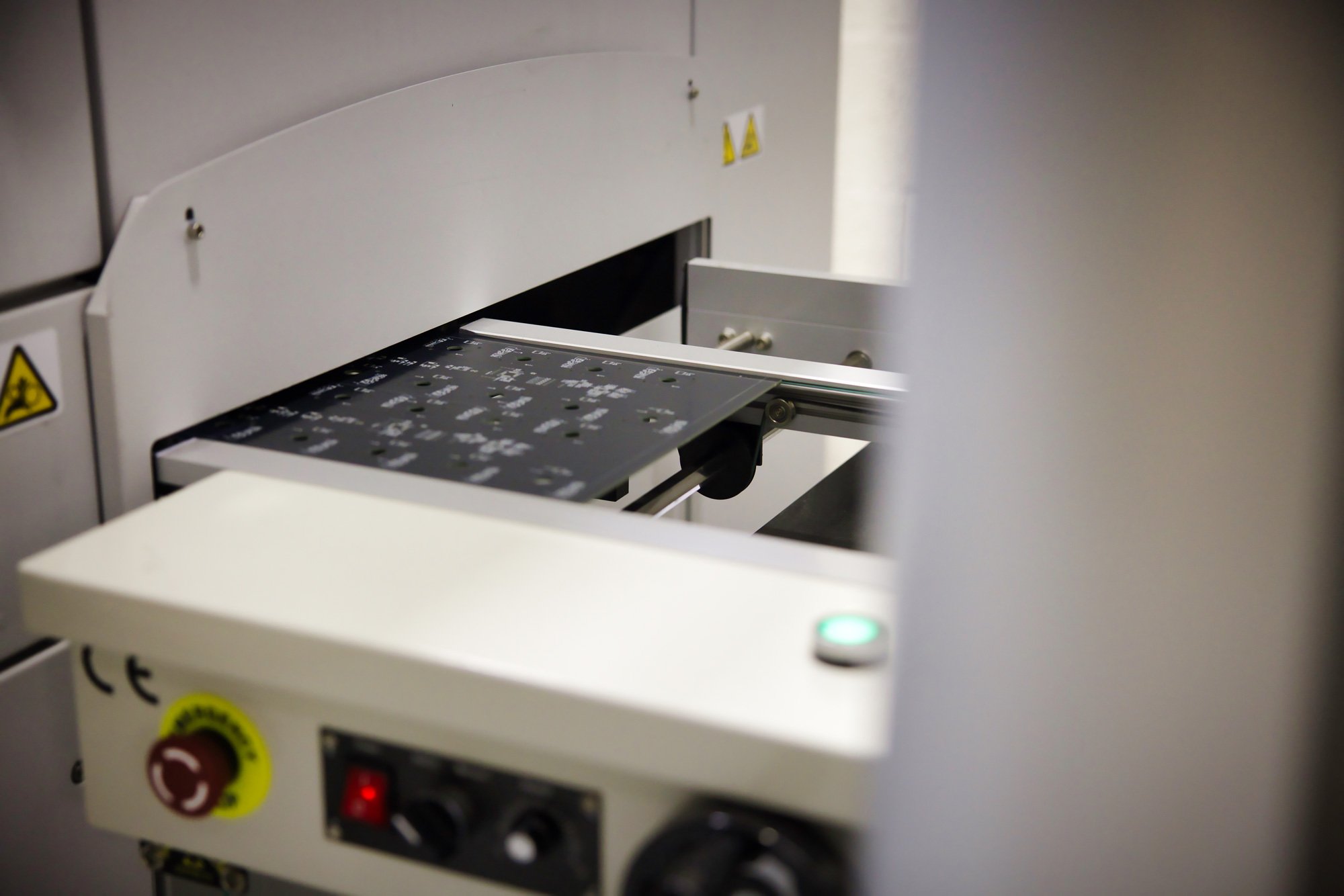

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors