Through-Hole PCB Assembly

Through-hole assembly is a traditional PCB assembly method where component leads are inserted into drilled holes and soldered on the opposite side. While often used for high-reliability applications, it remains a valuable option for specific components and designs. This page explains when and why through-hole assembly is preferred

Do not hesitate to get in touch with any questions you may have.

• 01384 891991

• enquiries@firstchoiceassembly.co.uk

1. What is through-hole PCB assembly?

Through-hole PCB assembly is a method where component leads are inserted into pre-drilled holes on the board and soldered on the opposite side. It is a traditional assembly technique still used for certain applications requiring mechanical strength and reliability.

This approach is commonly applied to connectors, large components, or parts subjected to mechanical stress. Through-hole assembly provides a robust connection that is ideal for durable and high-reliability electronics.

2. When should I use through-hole over SMT?

Through-hole assembly is preferred when components need extra mechanical support or when handling high-current applications. It is also chosen for prototypes or designs that require manual testing and modifications.

SMT is better for high-density boards, but through-hole remains valuable for boards exposed to vibration, heat, or mechanical stress. Choosing the right method depends on the design requirements and end-use environment.

3. What are the benefits of through-hole components?

Through-hole components offer stronger mechanical bonds compared with surface-mounted parts, making them suitable for connectors and heavy components. They also tolerate higher temperatures and mechanical stress during operation.

Another benefit is that they are easier to handle during manual assembly or repair. This makes through-hole suitable for low-volume production, prototyping, or specialised applications.

If you have any questions about our PCB Assembly services?

Get in touch with our team and we can answer them. 01384 891 991

We can supply you with a detailed quote for your printed circuit board assembly project.

4. Are through-hole PCBs more reliable?

Through-hole PCBs are generally more reliable for applications that require physical durability. The soldered leads create strong electrical and mechanical connections that withstand stress and vibration.

However, reliability also depends on the quality of assembly and inspection. Professional assembly ensures the board performs consistently under its intended conditions.

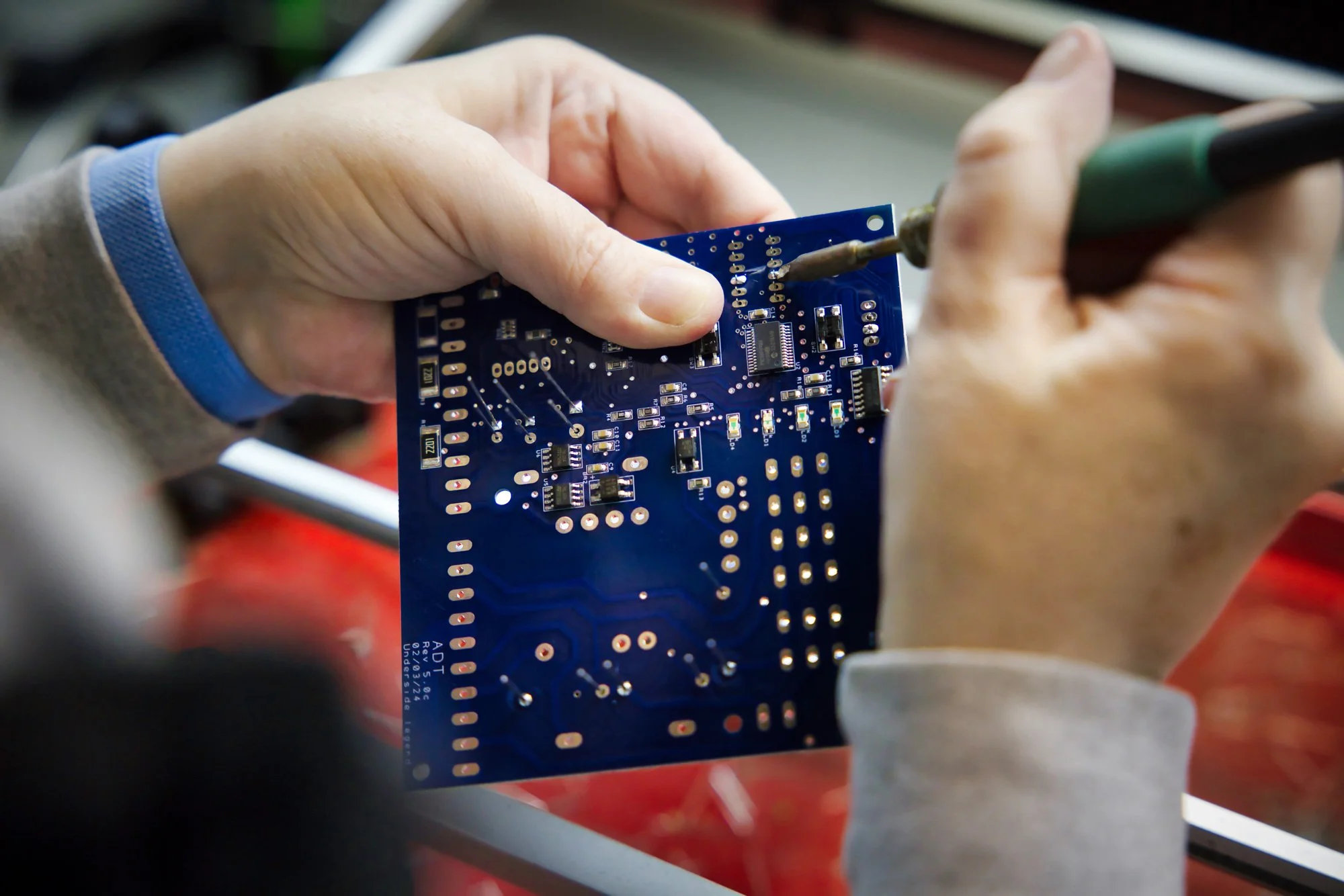

5. How is through-hole soldering performed?

Through-hole soldering can be done manually using a soldering iron or automatically via wave soldering machines. Components are inserted through the holes, soldered on the opposite side, and inspected for proper connection.

Wave soldering is ideal for medium to high-volume production, ensuring consistent solder joints across multiple boards. Manual soldering is typically used for prototypes or small batches.

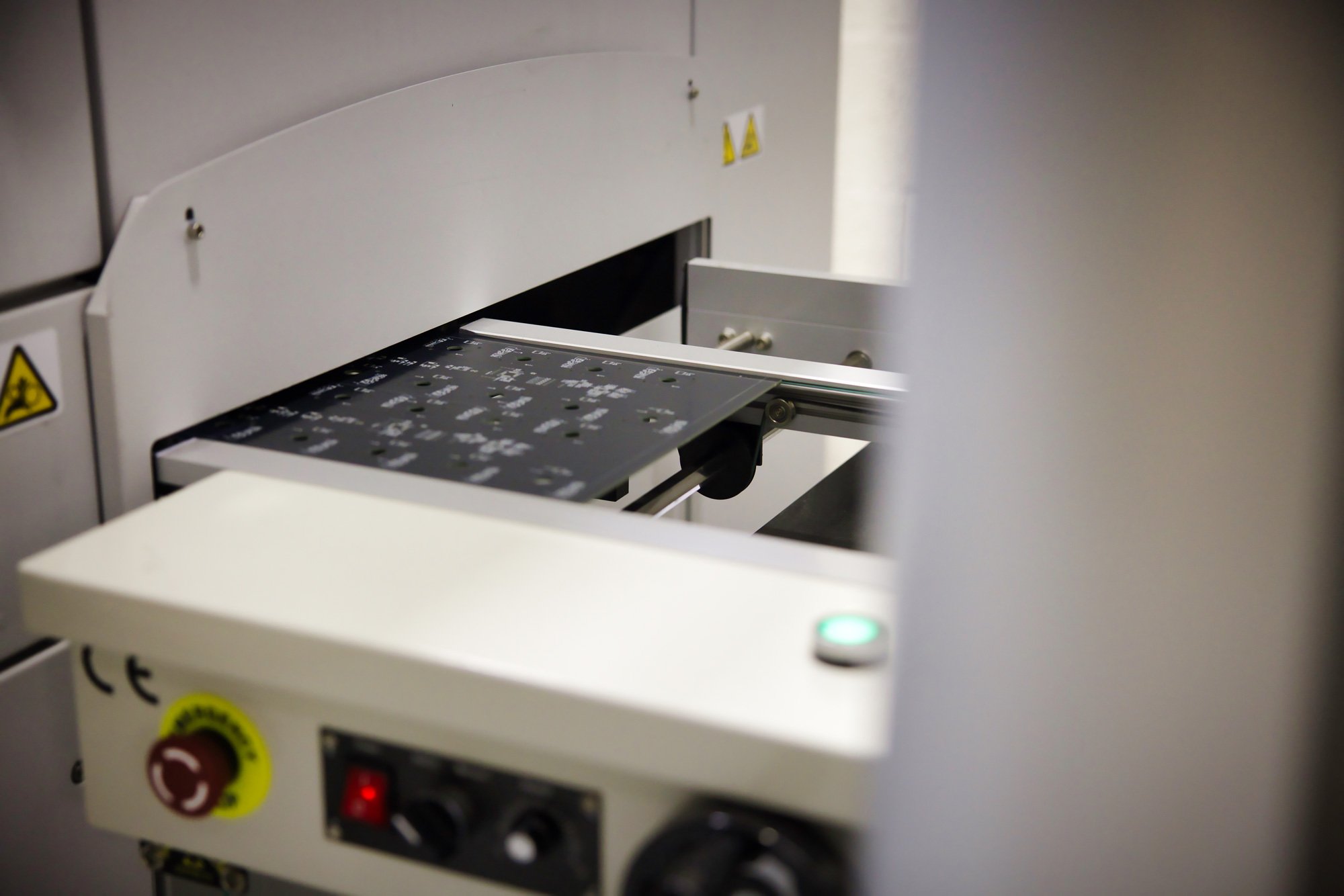

6. Can through-hole assembly be automated?

Yes, through-hole assembly can be automated using wave soldering or selective soldering machines. Automation increases production speed, consistency, and quality for high-volume projects.

Despite automation, manual inspection is still recommended for critical components to ensure reliability. Skilled operators can correct any defects or alignment issues.

7. What defects are common in through-hole PCBs?

Common defects include cold solder joints, solder bridges, lifted pads, and misaligned components. These can result from improper soldering temperature, incorrect flux application, or handling errors.

Quality control processes, including visual inspection and electrical testing, help identify and correct defects before boards leave the facility. This ensures reliable and fully functional PCBs.

8. How much does through-hole PCB assembly cost in the UK?

Through-hole PCB assembly costs vary depending on component count, board complexity, and production volume. Low-volume prototypes may be higher per unit, while larger production runs reduce cost per board.

Additional factors such as testing, inspection, and specialised components can also affect the price. UK-based providers offer competitive rates while ensuring high-quality standards and compliance.

9. How long does through-hole assembly take?

Through-hole assembly timelines depend on the number of components, board complexity, and production volume. Small prototype boards can be completed in a few days, while large production runs may take several weeks.

Planning, scheduling, and reliable supply of components help minimise delays. Working with an experienced UK assembler ensures timelines are met without compromising quality.

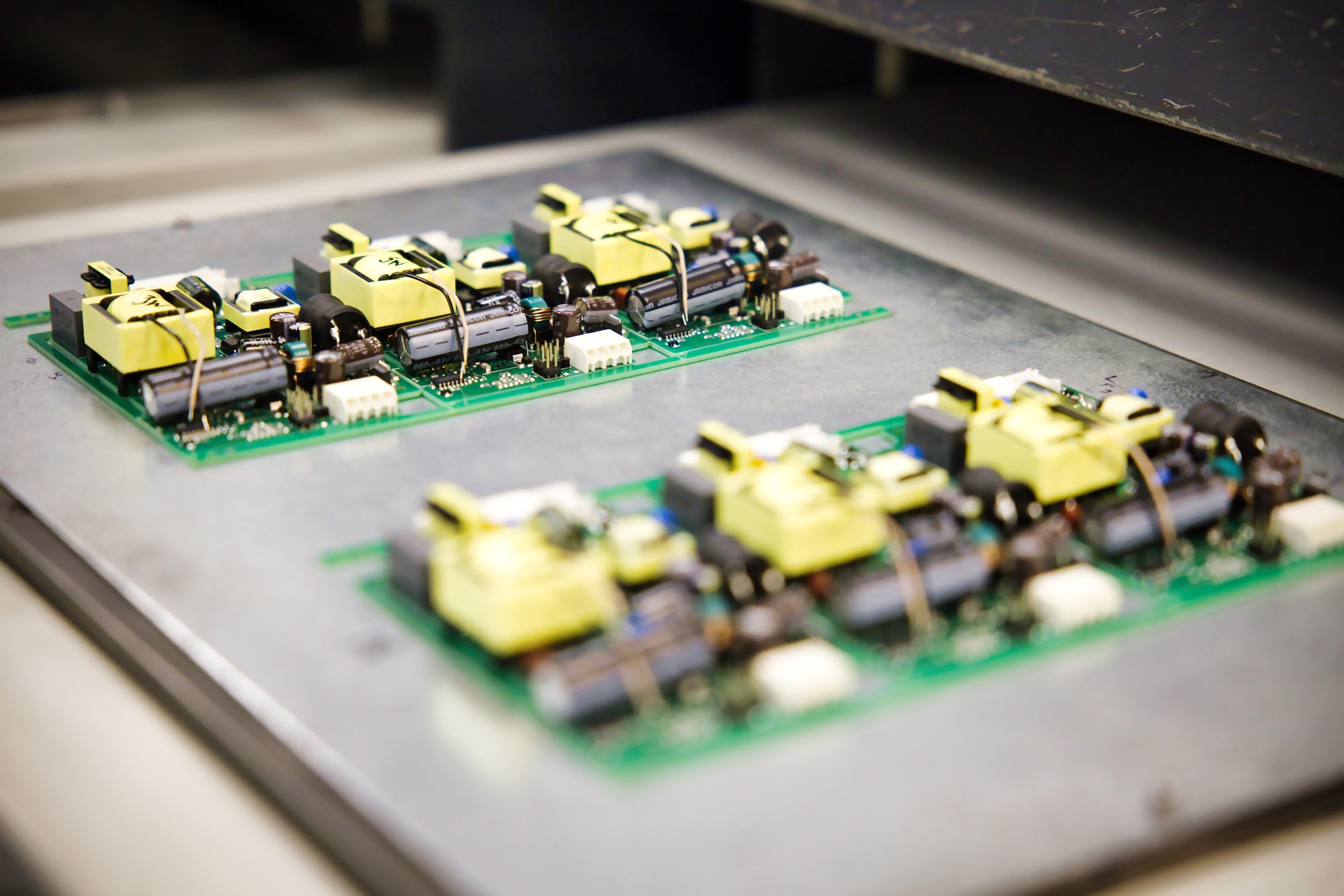

10. What types of components are best for through-hole?

Through-hole assembly is ideal for connectors, large capacitors, transformers, and high-power components. These parts benefit from the mechanical strength provided by leads inserted through the PCB.

Other suitable components include switches, relays, and certain ICs that require robust connections. Designers often combine through-hole and SMT components to optimise performance and reliability.

Helping our partners to produce cost effective quality products.

Experience, reliability and quality.

At First Choice Assembly we specialise in the manufacture and assembly of printed circuit boards for a wide range of applications. We manufacture surface mounted printed circuit boards, conventional or hybrid PCBs, all made to our partners specification.

Here at First Choice Assembly we have 30 years experience of PCB assembly and manufacturing and within this time we have dealt with and supplied printed circuit boards to a large number of industry sectors